Grinding robots compared: Universal Robots vs. Yaskawaa

With our grinding robots, we offer two powerful solutions for different surface finishing requirements.

Our grinding robots offer state-of-the-art solutions for automated surface finishing – whether for small, flexible components or large production runs. With our two systems, the Universal Robots grinding robot and the Yaskawa ArcWorld Evo , customers can select the right technology for their individual requirements. The following comparison outlines the strengths and applications of each system.

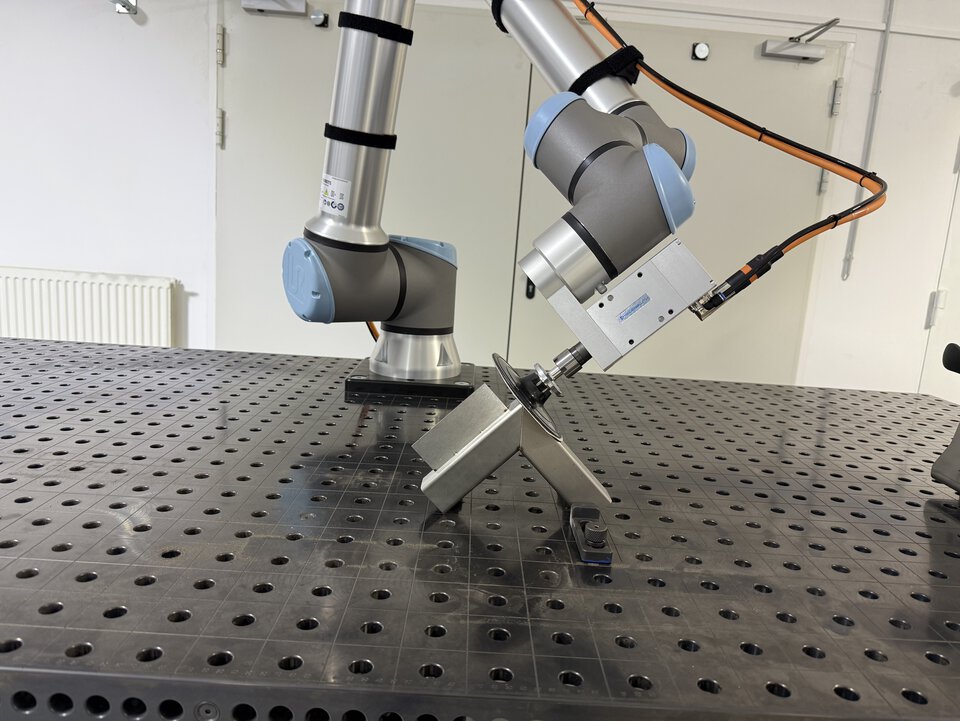

Universal Robot grinding robot

The Universal Robots grinding robot is based on the flexible UR cobot arms and is ideally suited for small to medium-sized workpieces.

Thanks to intuitive programming via the teach pendant, it can be set up quickly, is suitable for collaborative use, and adapts flexibly to different component geometries. An integrated force/torque sensor system ensures constant contact pressure, guaranteeing consistent grinding and polishing results. Tools can be easily exchanged via quick-change systems, reducing downtime and increasing efficiency. Typical applications include grinding, polishing, or deburring a wide variety of components.

Yaskawa grinding robot

The Yaskawa ArcWorld Evo grinding robot is designed for productive multi-sided machining of larger components.

Equipped with a rotary/tilting table, it enables the removal of discoloration and the precise grinding of weld bead protrusions from multiple directions. The powerful drive unit with pressure compensation module ensures a uniform grinding pattern, while the fully automatic tool changer guarantees consistent grinding quality. The ArcWorld Evo robotic cell is particularly robust and efficient, designed for series production, and ideal for customers who want to process large quantities with minimal manual intervention.

Conclusion: Universal Robots grinding robot vs. Yaskawa grinding robot

The Universal Robots grinding robot is particularly impressive due to its flexibility and ease of use.

Thanks to its intuitive programming, collaborative application options, and precise sensor technology, it is ideally suited for small and medium-sized components as well as for production processes with a wide variety of workpieces. Those who need to react quickly to different requirements will benefit from the high adaptability of this system.

The Yaskawa ArcWorld Evo grinding robot, on the other hand, is ideally suited for the productive machining of larger components and series production. With its integrated rotary/tilting table, automatic tool changer, and powerful drive unit, it ensures a consistent and high-quality grinding finish – even with complex multi-sided machining operations. Customers who value consistent quality, efficiency, and minimal manual intervention will find the perfect solution in the ArcWorld Evo robotic cell.

Both systems therefore offer unique advantages: While the Universal Robots robot emphasizes flexibility and rapid adaptation, the ArcWorld Evo scores points with high productivity and consistent results in series production.