TwinArc Cobot Edition - Flexibility and Efficiency

A modern production line stands or falls on its flexibility and output – characteristics that are the focus of this advanced 2-station system.

With the ability to be flexibly deployed in various production processes, this complete solution offers numerous manufacturing companies a clear optimization in terms of efficiency and productivity.

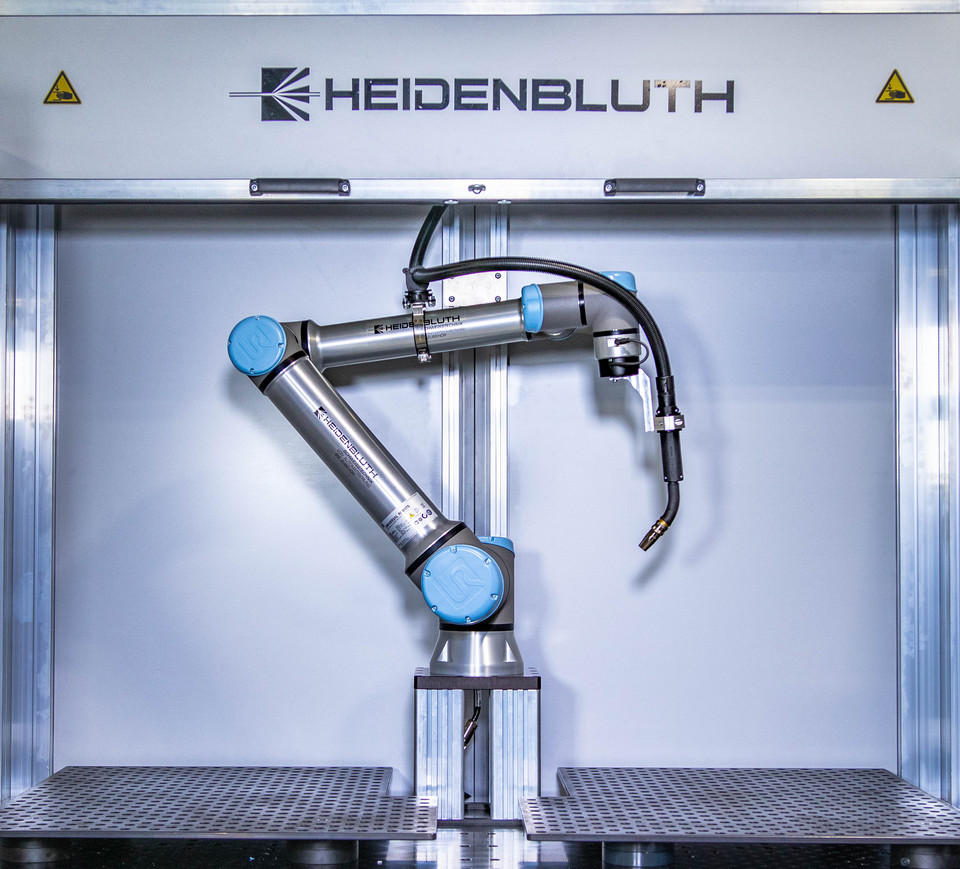

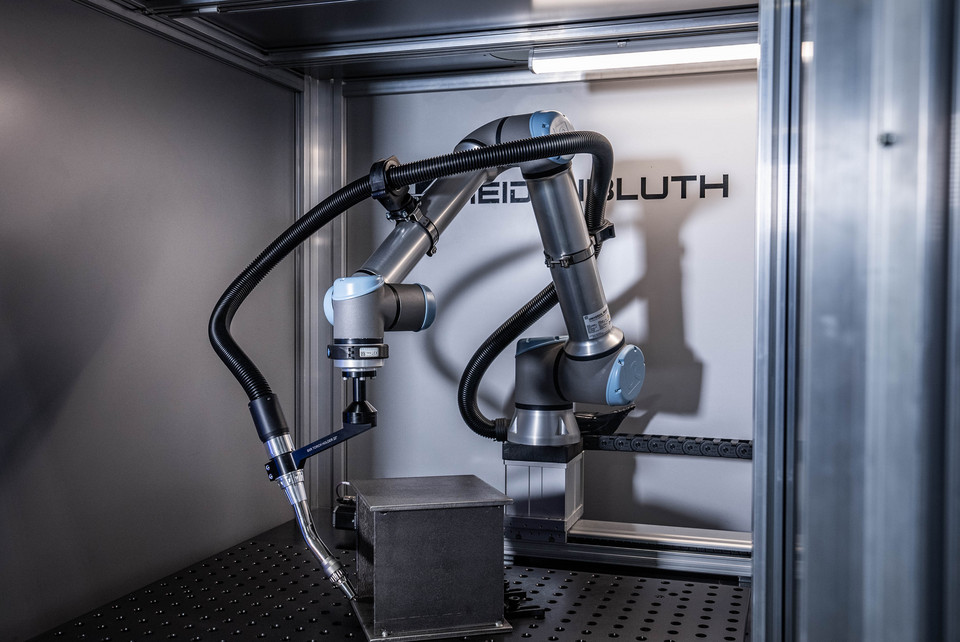

![[Translate to English:] Heidenbluth - TwinArc Cobot Edition [Translate to English:] Heidenbluth - TwinArc Cobot Edition](/fileadmin/_processed_/8/e/csm_DSC08433_26258a0160.jpg)

- 1

Siegmund welding table

- 2

Cobot from Universal Robots

- 3

Linear axis

- 4

Different welding processes

- High output : Efficient processes ensure increased production capacity.

- Flexibility : Versatile use in manufacturing thanks to its 2-station design.

- Forklift compatibility : Easy and quick relocation within the production hall.

- Closed system : Ready for extraction systems, improves air quality and cleanliness.

- Plug&Play complete solution : Ready for immediate operation with integrated system control.

- Work area lighting : Optimal visibility conditions for operators.

- LED operating status indicator : Quick status overview at a glance.

- Complete safety features : CE compliant for maximum protection.

- Plant enclosure with viewing window : safety and process monitoring in one.

- Cobot from Universal Robots UR10e

- Dimensions of the system

- Width: 3150mm

- Depth: 2000mm

- Height: 2200mm

- Possible workpiece sizes/clamping surface

- Width: 1150mm

- Depth: 990mm

- Height: *max 700mm

- MIG/MAG from EWM

- MIG/MAG from Fronius

- CMT - Cold Metal Transfer by Fronius

- WIG-DC from EWM

- EWM TIG AC/DC

- TIG DC with cold wire feed from EWM

- TIG AC/DC with cold wire feed from EWM

- With protective film for UR e-Series

- With protective cover for control panel

- With lighting

- Cobot LED Lighting traffic light

- Pneumatic zero-point clamping system for holding Siegmund interchangeable plates

High output through innovative technology

The 2-station solution is designed to ensure high output through optimized processes.

The automation and efficient processes of the plant enable an increase in production capacity, which not only reduces throughput times but also saves costs in the long term.

Forklift capability and mobility

Another advantage of this system is its forklift-compatible design. This allows for easy and quick relocation within the production hall.

This allows the system to be flexibly relocated depending on production requirements without significantly disrupting ongoing operations. As a result, companies remain responsive and can optimally adapt their production lines.