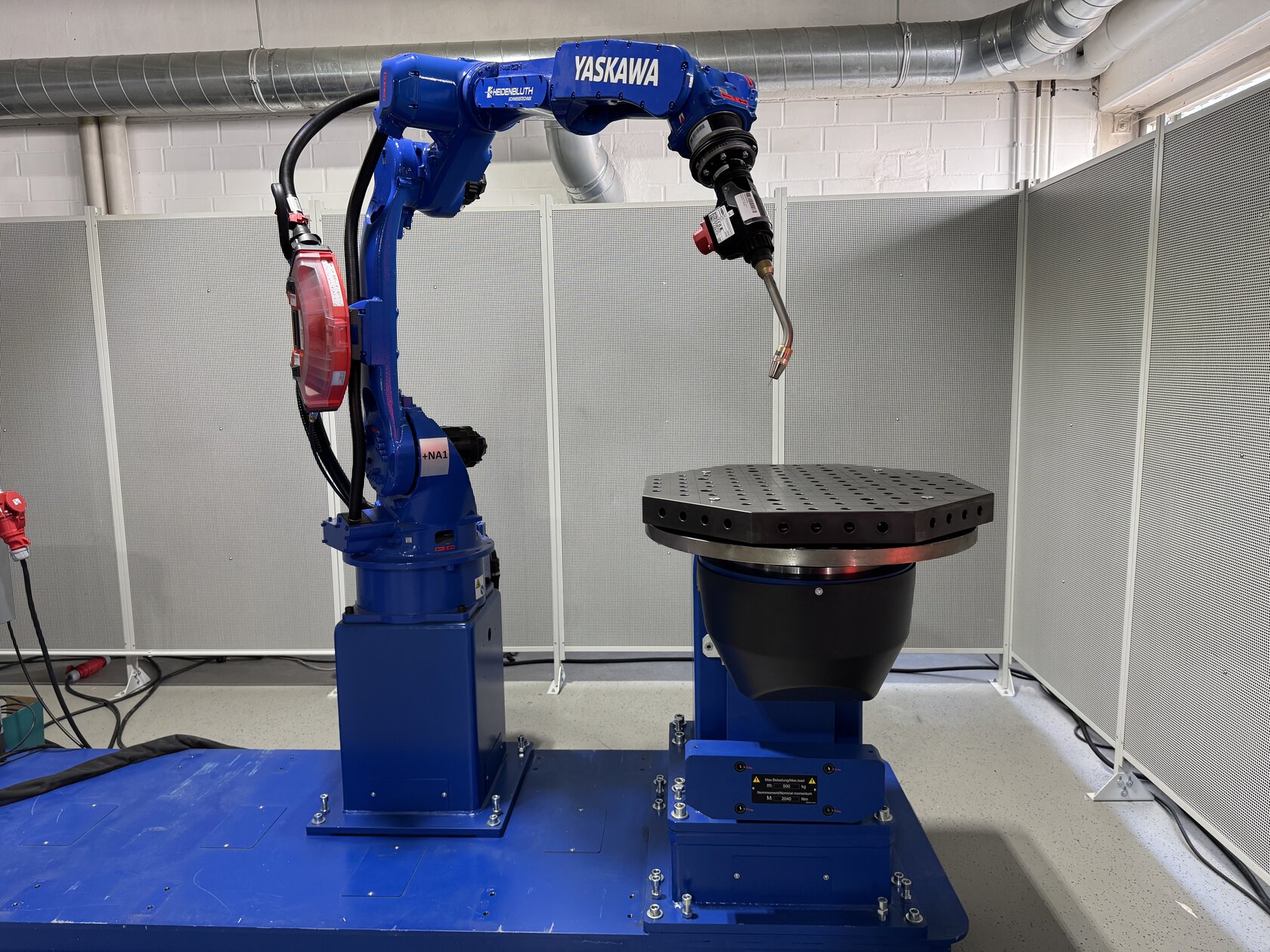

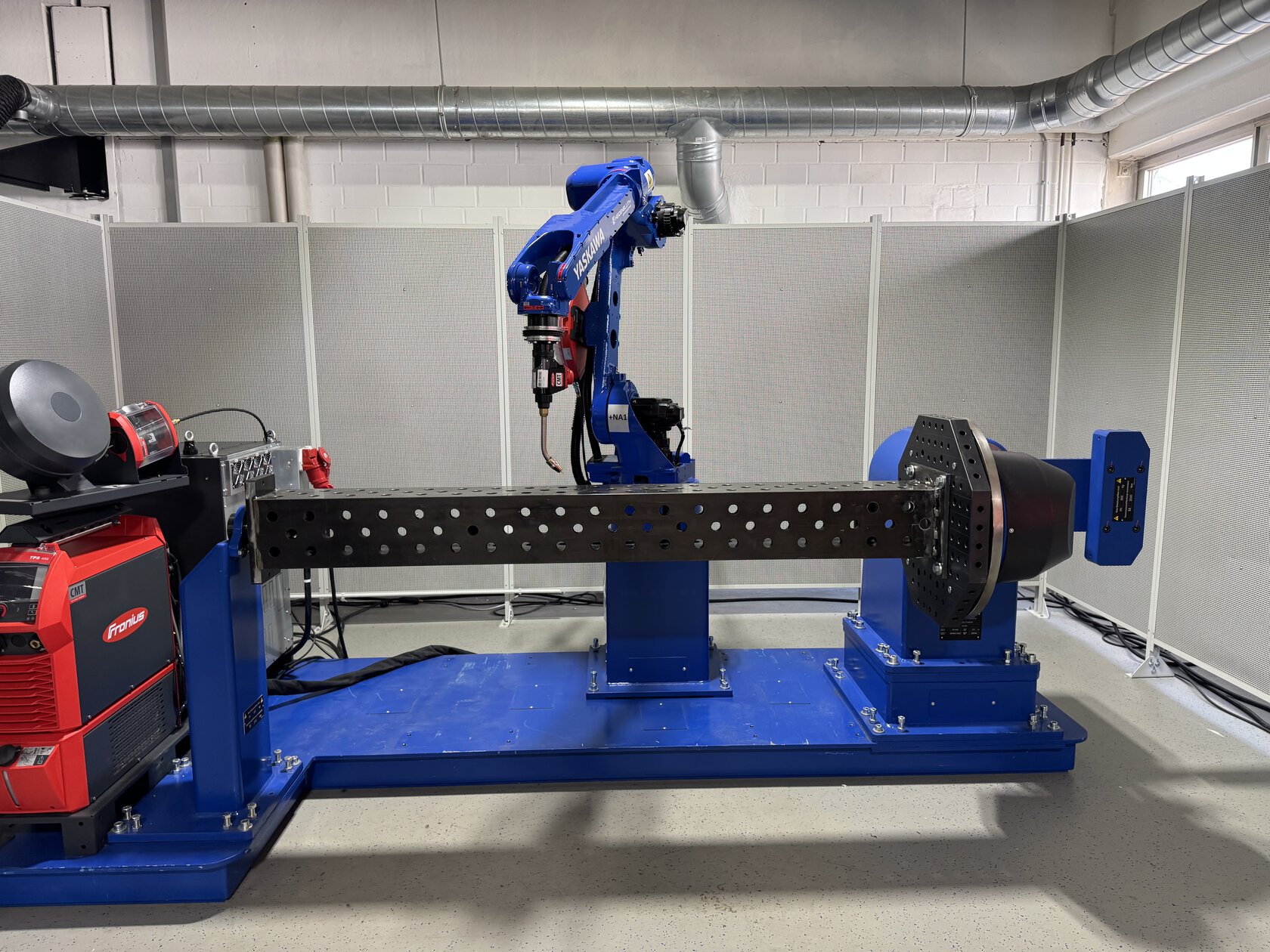

The ArcWorld EVO Plus is particularly suitable for complex welding tasks.

The ArcWorld Evo Plus is the ideal solution for complex welding tasks and also impresses with its suitability for larger components.

Thanks to a stable base frame and counter bearing, workpieces can be securely held. The integrated positioning technology with rotary/tilting table enables precise and fast machining of complex geometries.

![[Translate to English:] ArcWorld EVO Plus](/fileadmin/_processed_/3/b/csm_EVO_Plus_Hotspot_a2f40813f8.jpg)

- 1

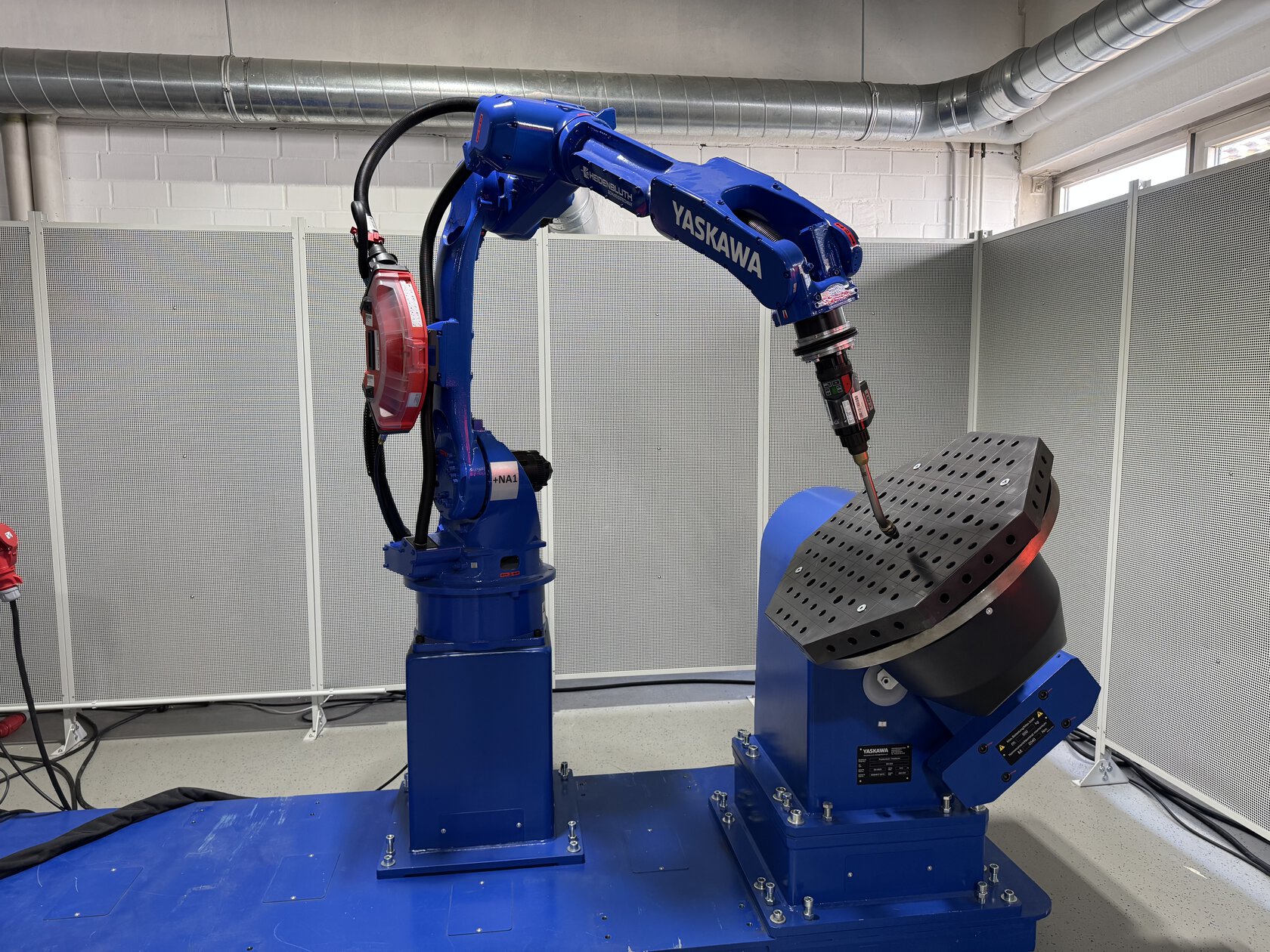

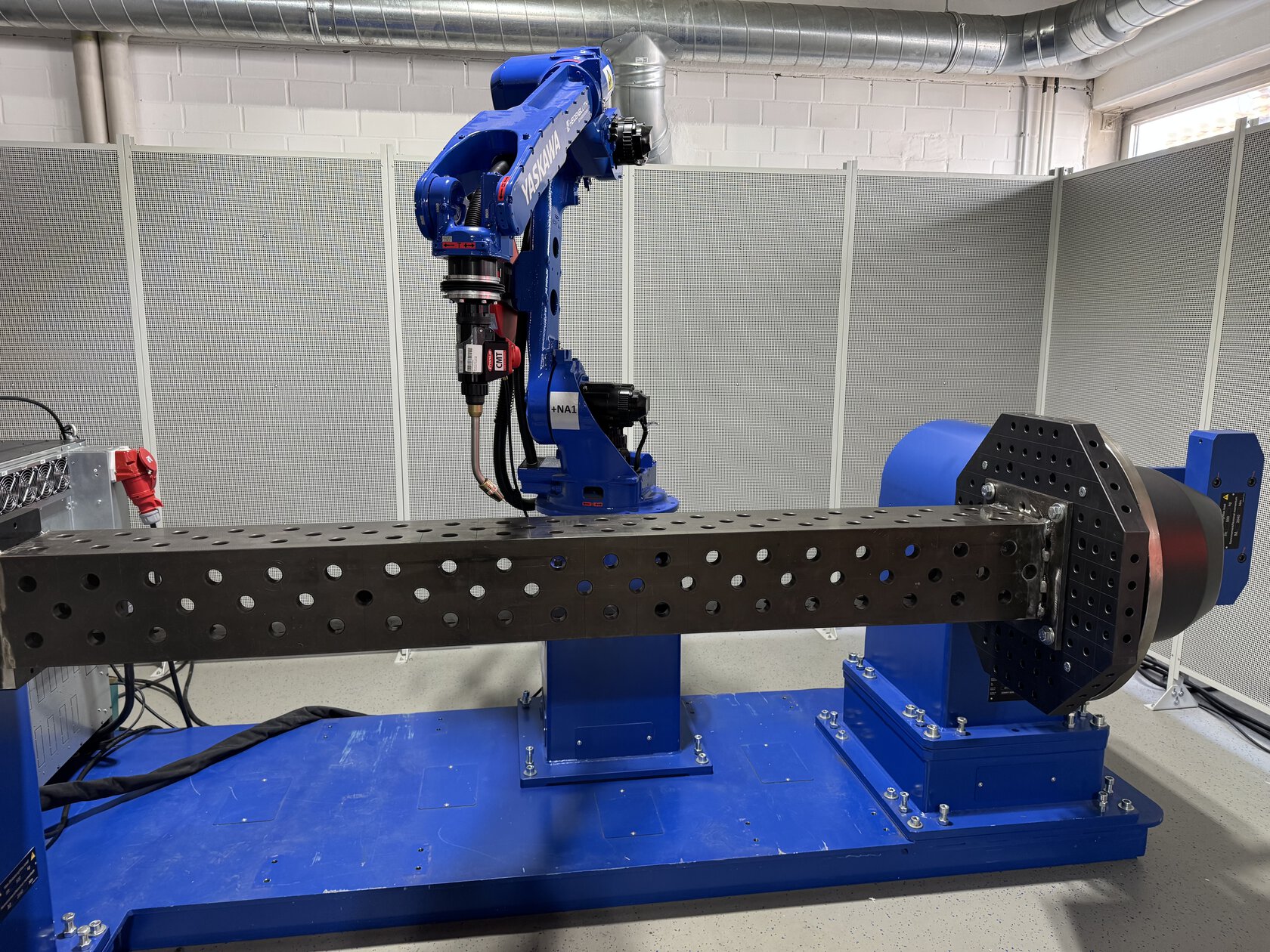

Yaskawa industrial robot for weld-off without a backing, with extensive additional functions

- 2

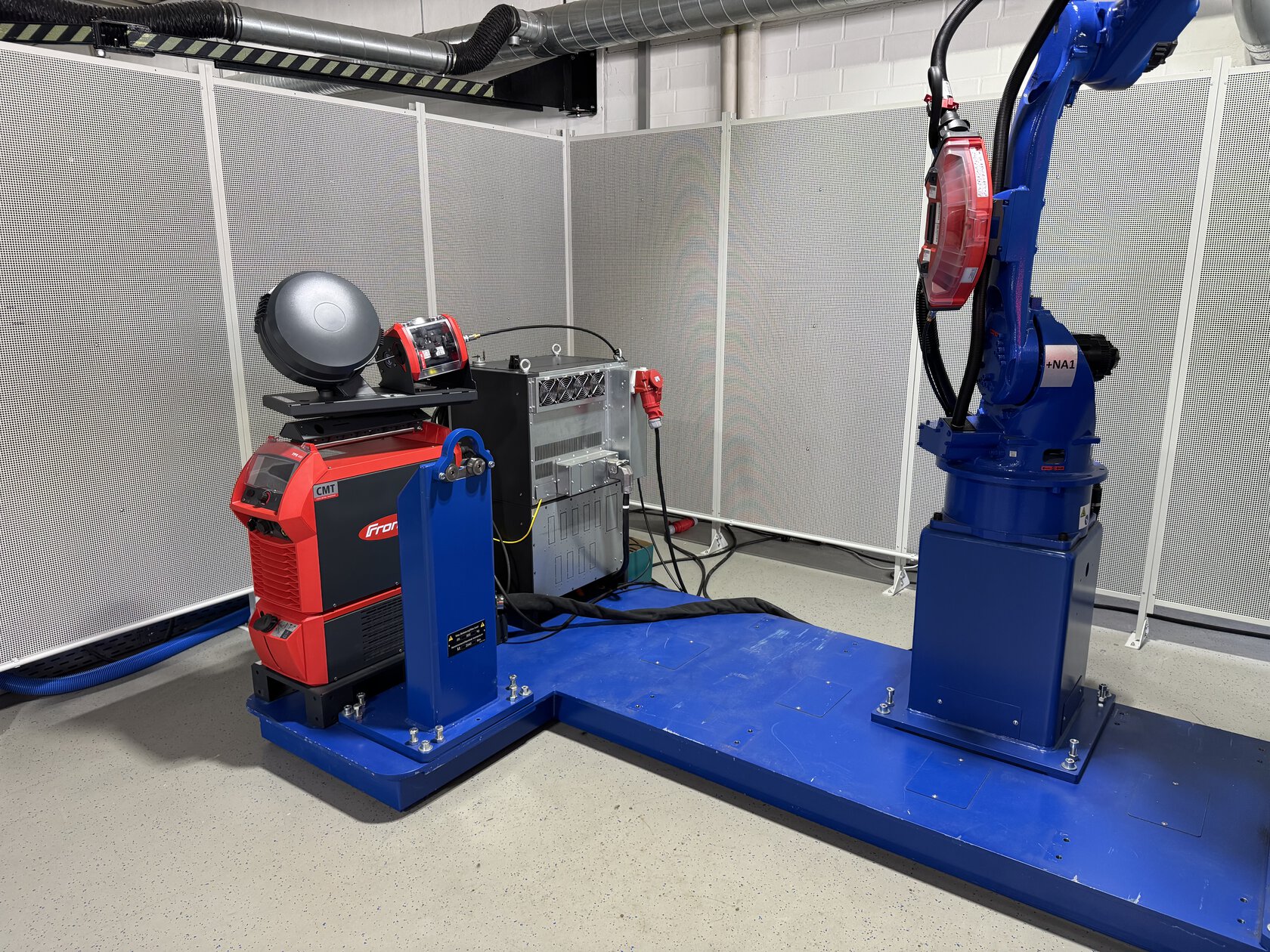

Welding technology

- 3

Rotary tilting table for optimal component positioning

- Short delivery time

- The rotary tilting table allows for the welding of complex components.

- Easy installation of the system

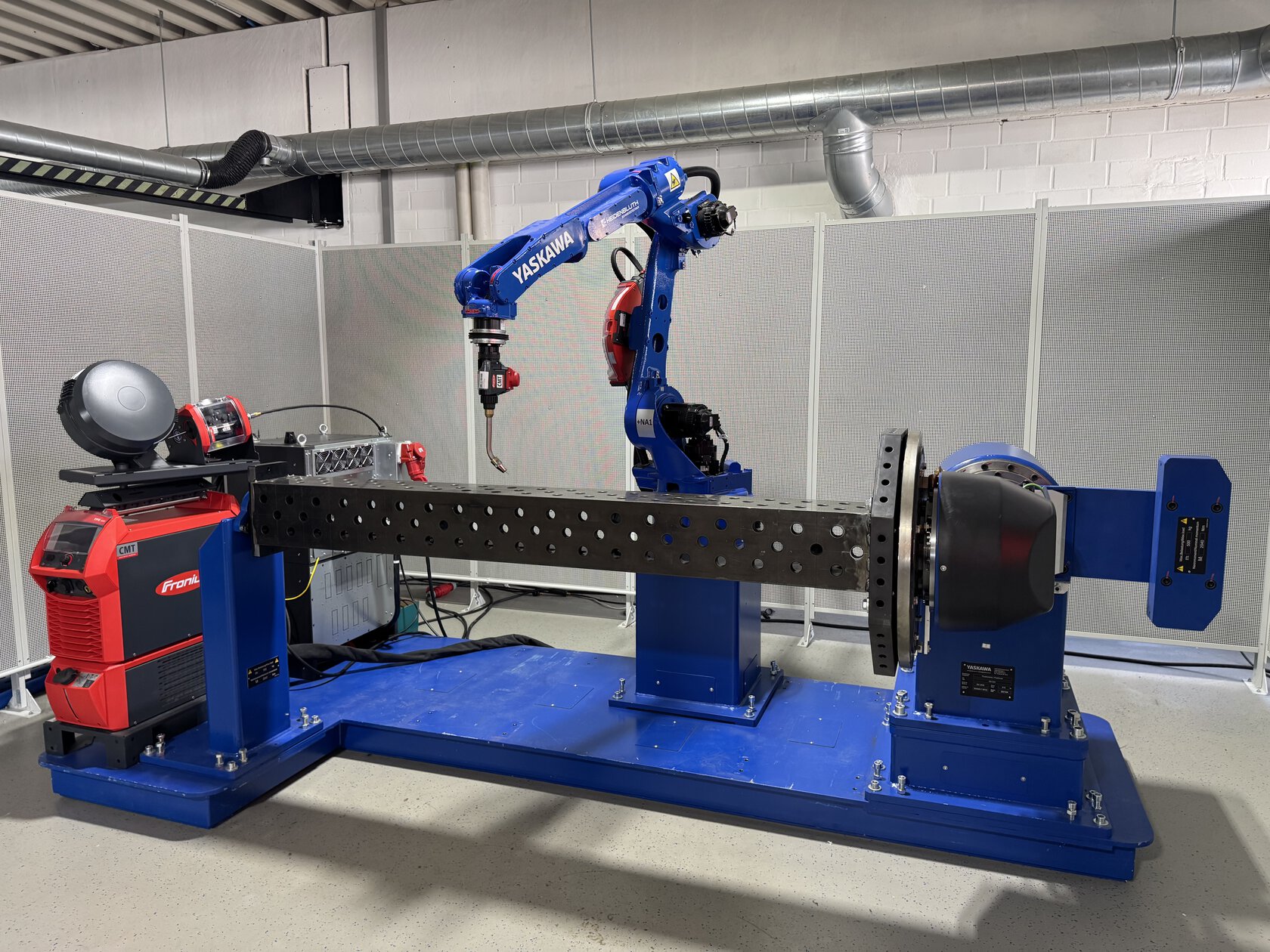

- Generous insertion area

- Prepared for offline programming

- CE Declaration of Conformity for the entire system

- CE Declaration of Conformity for the entire system

- Positioning technology using a rotary/tilting table

- MIG/MAG from EWM

- MIG/MAG from Fronius

- CMT - Cold Metal Transfer by Fronius

- WIG-DC from EWM

- EWM TIG AC/DC

- TIG DC with cold wire feed from EWM

- TIG AC/DC with cold wire feed from EWM

- stud welding technology

- Pneumatic zero-point clamping system for holding Siegmund interchangeable plates

- Siegmund Octagonal Table Plasma Nitrided

- Automatic tungsten electrode changer

- Automatic contact nozzle changer

- Ground track for linear travel path

The ArcWorld EVO Plus – The solution for complex welding tasks

With a maximum turning diameter of 1,600 mm and a center distance of 2,000 mm, the system offers generous capacities. The center distance can be optionally extended by means of a floor track, allowing the robot to move flexibly in a linear fashion. All axes are designed as synchronous axes – for simpler programming and rapid reorientation during component movements.