Additional axes & positioners

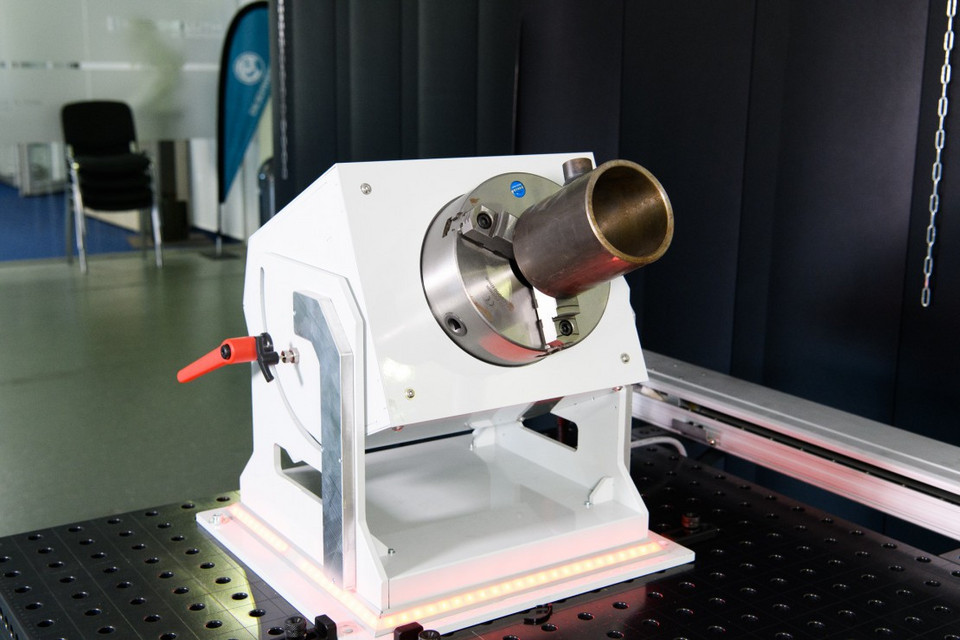

Positioners and rotary tilt tables

We offer a wide variety of different positioners and rotary tilt tables.

Depending on component ergonomics, welding position, and weight, we select the appropriate positioning technology for you. Full synchronization capabilities allow for optimal coordination of accessories and robot movements. Operation is intuitive via a programming handheld device.

FLOOR SUSPENSION

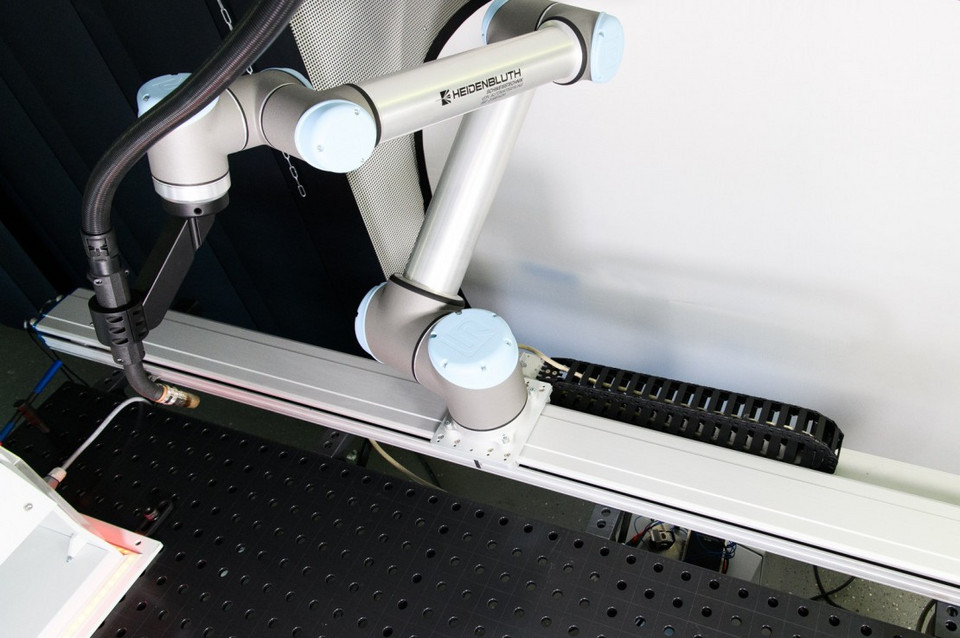

Floor-mounted chassis make it possible to quickly move the welding robot to the desired welding position.

A ground-based chassis is a particularly useful addition for larger components. Mounting it on gantries further extends the robot's reach.

Additional axes & positioners

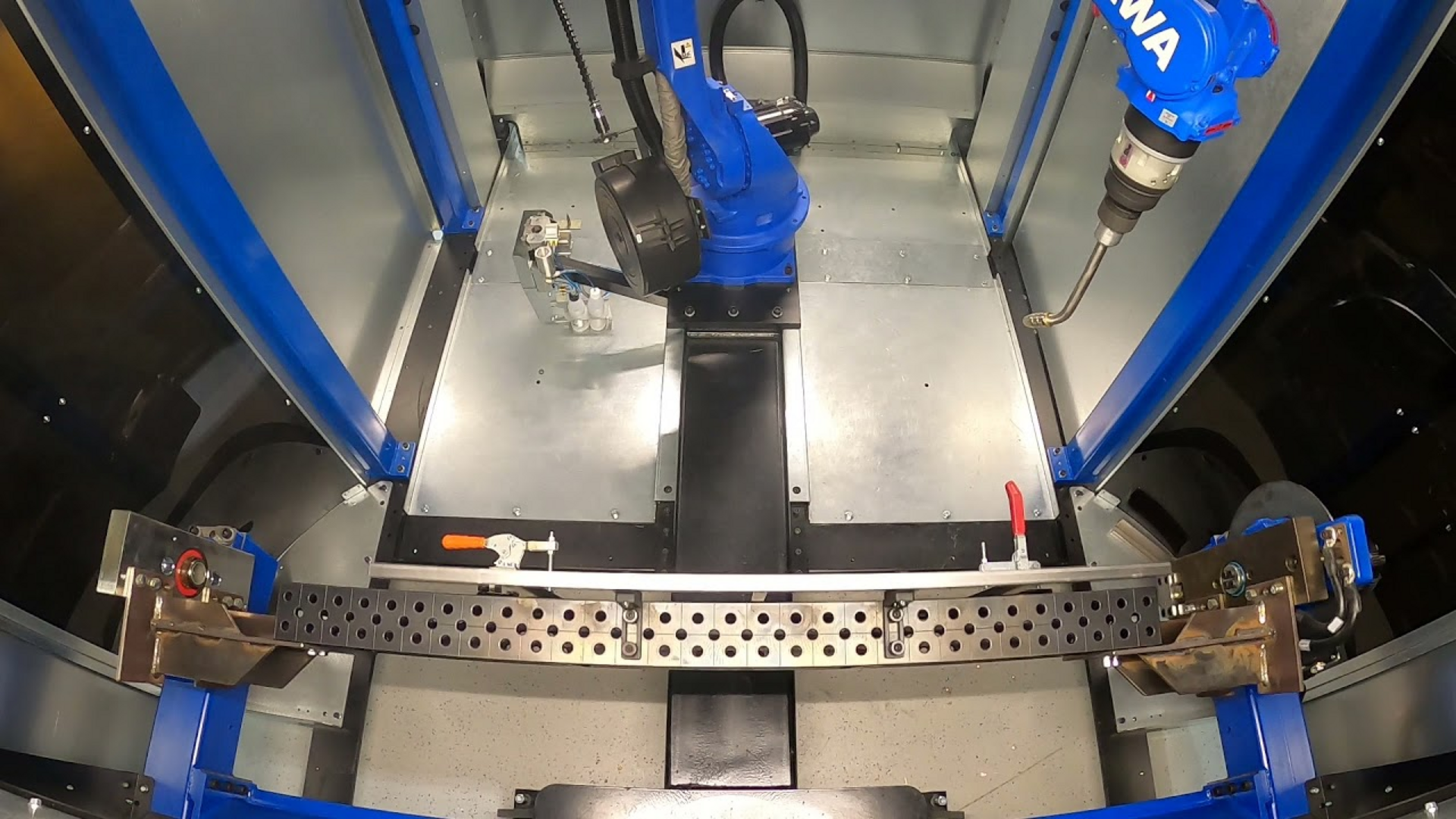

Various component positioners allow for optimal access to hard-to-reach weld seams and positioning them in the ideal welding position. Linear axes or tracks enable the robot to move linearly to the component. This makes it possible to process two spatially separated welding stations without an additional rotary axis beneath the positioner – a particularly advantageous solution for larger components.

These linear axes or tracks can either be positioned behind the assembly or mounted on a gantry. Rotary axis positioners are also used to create two-station systems. This increases productivity, as assembly and welding can be performed simultaneously.

Function:

These additional axes are integrated with the robot and our controller. This allows the positioning axes to be operated as a 7th/8th axis. A key advantage is that the positioner's movement can be synchronized with the robot, which reduces the robot's reorientation time and significantly simplifies programming.