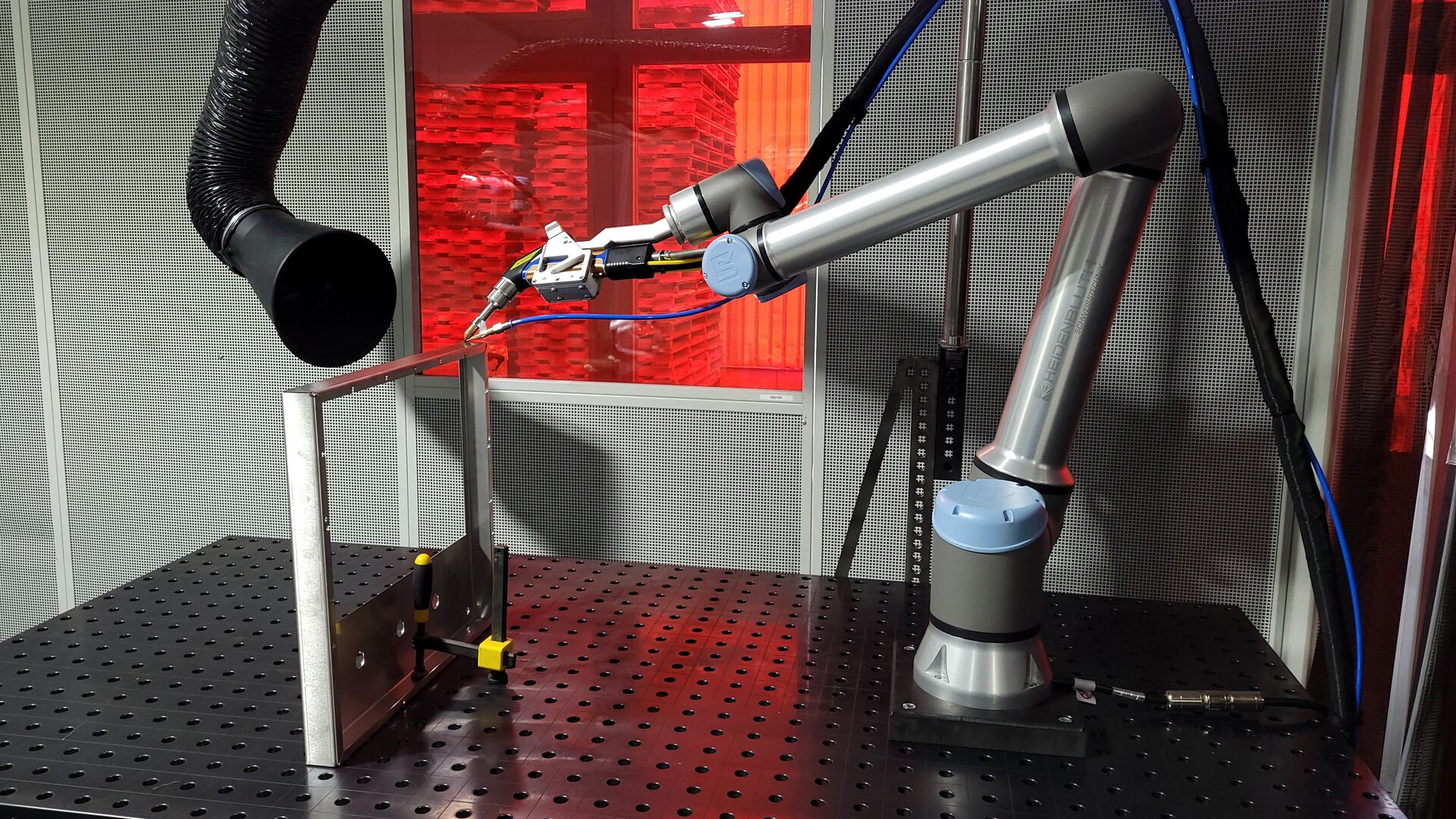

Welding Package Cobot Laser

The Welding Package Cobot Laser is a comprehensive welding system that combines robotics, laser technology, and safety in one innovative solution. It was specifically developed to enable highly precise and efficient laser welding while ensuring the highest safety standards.

Thanks to the combination of modern automation technology and advanced laser technology, the system offers a precise, fast, and material-friendly welding solution that is ideally suited for industrial applications. The integrated safety mechanisms ensure that the entire welding process runs reliably and in accordance with standards, thereby raising product quality and workplace safety to a new level.

- 1

Siegmund welding table

- 2

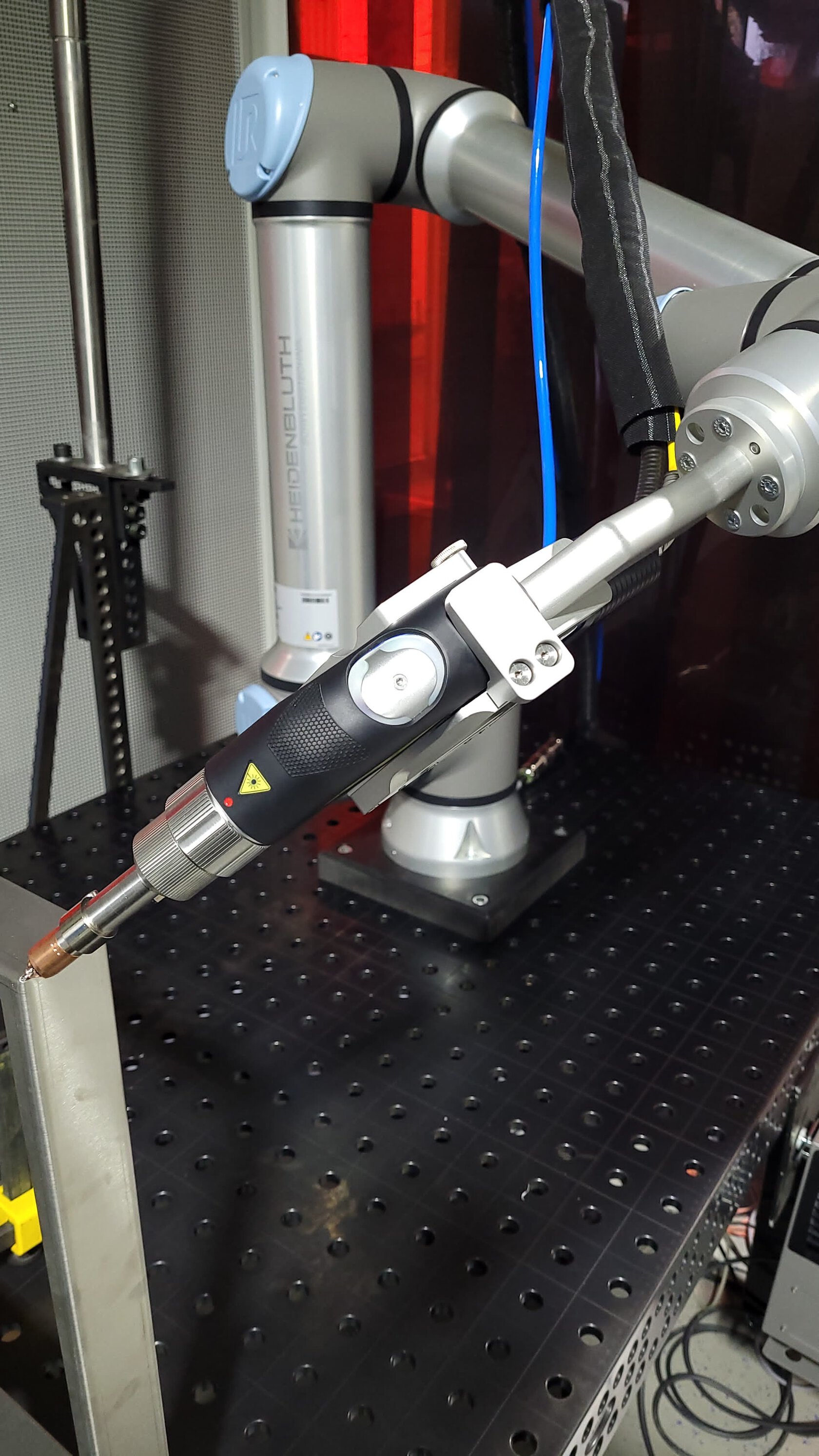

Laser technology

- 3

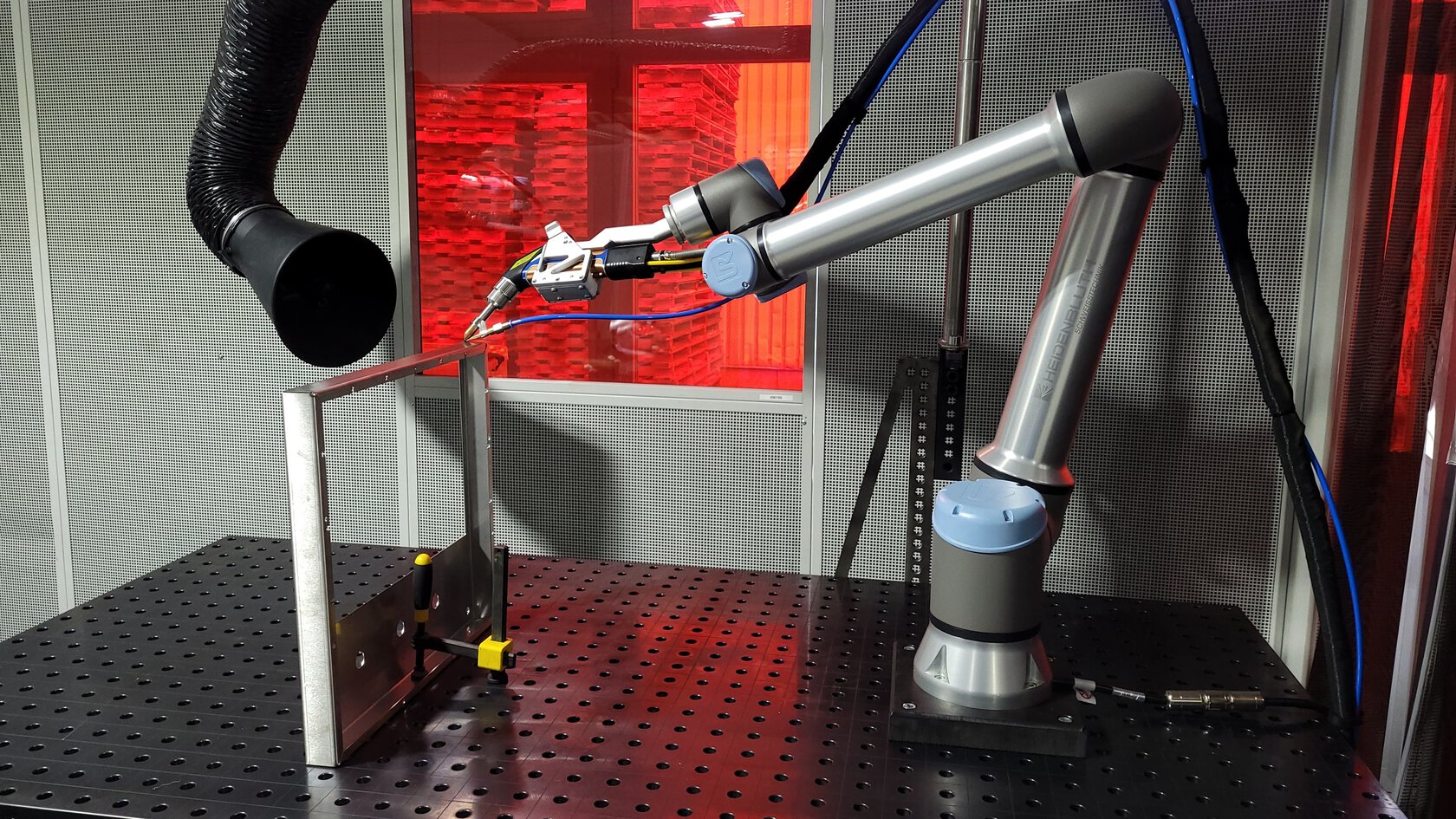

Cobot from Universal Robots

- Convenient access to the welding area without interfering contours for loading and unloading.

- The cabin can be freely configured in terms of size and flexibility.

- Self-built enclosure after agreement on minimum requirements

- Siegmund welding tables offer space for all assemblies

- Mounting the robot on the table or optionally on the back wall

- Standard enclosure, soundproof enclosure or optional self-build

- including safety technology

- Installation and commissioning by our technicians at a fixed price

- On-site training by our technicians at your location for a fixed price

- Welding processes : Supports MIG/MAG and TIG processes, ideal for different applications and materials.

- Robot arm reach : Up to 1,300 mm, for flexible adaptation to different workpiece sizes.

- Robot payload capacity : 5 to 10 kg, suitable for most welding applications in industrial environments.

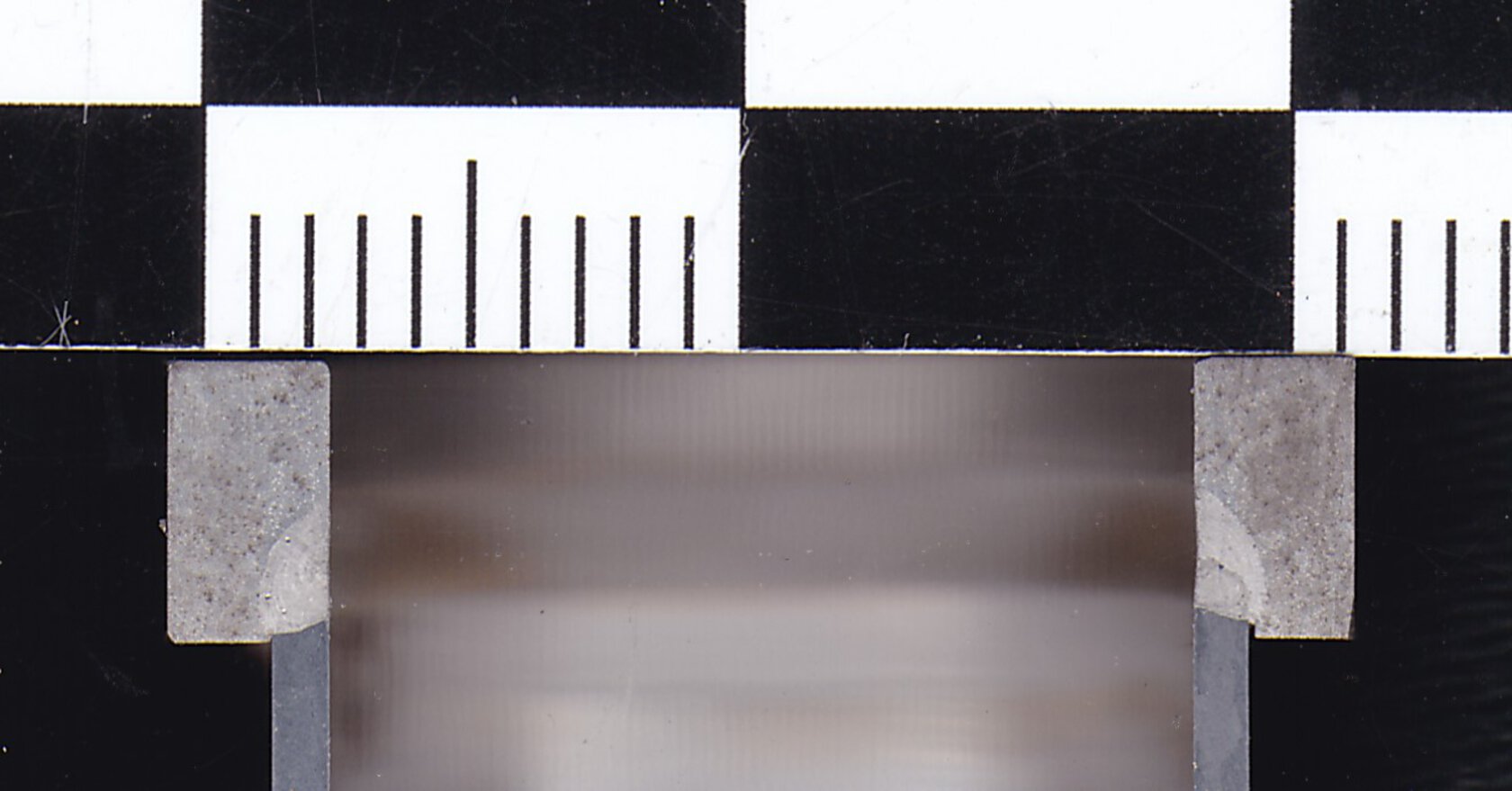

- Repeatability : ± 0.03 mm, ensuring high precision and consistent weld quality.

- Control and programming : Touchscreen and offline programming enable simple and intuitive operation.

- CE certification for the entire system : legal certainty and full conformity, thus eliminating the need for a separate risk assessment.

The laser cabin is specifically designed for welding systems and meets the requirements of the corresponding laser class . It offers optimal protection while simultaneously reducing noise levels through the use of special soundproofing systems in all walls.

Features of the enclosure

- Safety standards

The cabin is equipped according to the requirements of DIN EN 60825-4:2011 and includes an entrance door with a laser window (60 x 60 cm) for safe visual inspection. - Enhanced safety technology:

The system is equipped with Pilz safety technology to ensure maximum safety for operators and bystanders. LED warning signs are included. - Efficient extraction:

Welding fumes are captured inside the cabin by a telescopic extraction arm and routed via an exhaust duct to the optional filter system. Integrated air inlets ensure effective air circulation. - Dimensions:

The standard cabin dimensions are 2.50 m wide, 3.50 m deep, and 2.70 m high . Other sizes are available upon request to meet individual requirements.

- MIG/MAG from EWM

- MIG/MAG from Fronius

- CMT - Cold Metal Transfer by Fronius

- WIG-DC from EWM

- EWM TIG AC/DC

- TIG DC with cold wire feed from EWM

- TIG AC/DC with cold wire feed from EWM

- With protective film for UR e-Series

- With protective cover for control panel

- Cobot LED Lighting traffic light

- Pneumatic zero-point clamping system for holding Siegmund interchangeable plates

Welding Package Cobot Laser

The Welding Package Cobot Laser with TIG welding technology and extensive accessories.

- Table size variable

- Robot type UR 5e or UR 10e "Ready to weld"

- Software packages for easier operation

- CE declaration for the entire system

- MIG/MAG welding technology Fronius and EWM

- Zero point clamping system

- burner extraction

- Linear axis for moving the robot

- Rotary table for component positioning

- Rotary and tilting table for component positioning

- TIG welding technology from Fronius or EWM

Precision laser welding of aluminum assemblies

Efficient, flexible and reliable – state-of-the-art technology for perfect welds.

In this application, an aluminum assembly is welded using a laser. Thanks to the integrated rotary tilt positioner, the component can be moved into the optimal welding position at any time. The push-pull drive ensures reliable wire feed – even during complex reorientations.

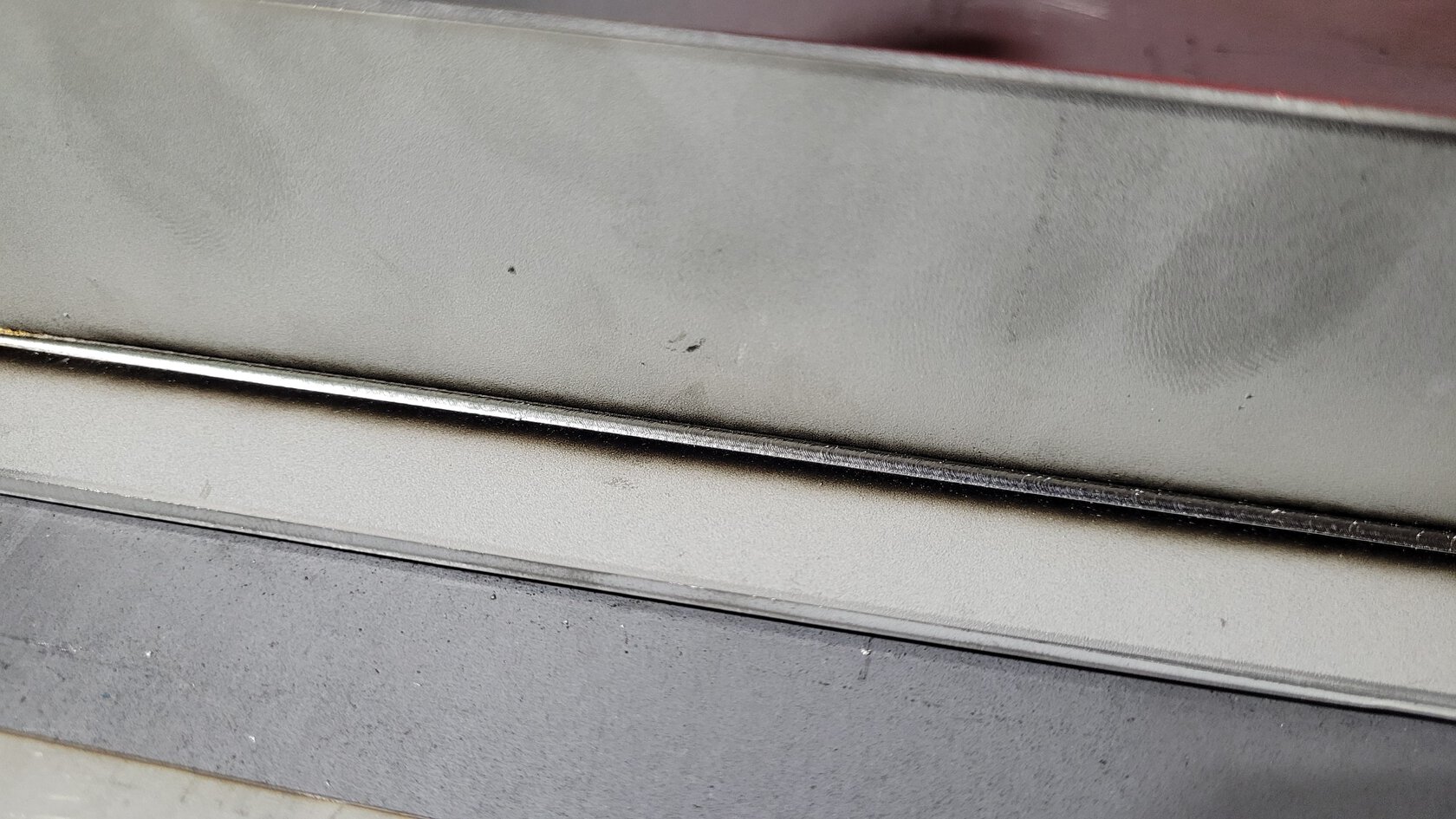

Precision laser welding of stainless steel containers

High quality and process reliability – for optimal welding results in demanding applications.

In this application, a stainless steel container is welded using a laser. The integrated rotary tilt positioner allows the component to be brought into the optimal welding position at all times. Simultaneously, the push-pull drive ensures reliable wire feed – even during complex reorientations.

Welding Package Cobot Laser

The Welding Package Cobot Laser is a complete welding system that combines state-of-the-art robotics, laser technology, and comprehensive safety solutions in one innovative, integrated solution. This system was specifically developed for high-precision and efficient laser welding processes and meets the highest safety standards. A key feature is the adaptable enclosure system, which can be individually configured to meet customer requirements. After installation, the customer receives a CE declaration for the entire system, ensuring legally compliant and safe operation. Additionally, component positioning technology is available as an extension to further optimize manufacturing processes.