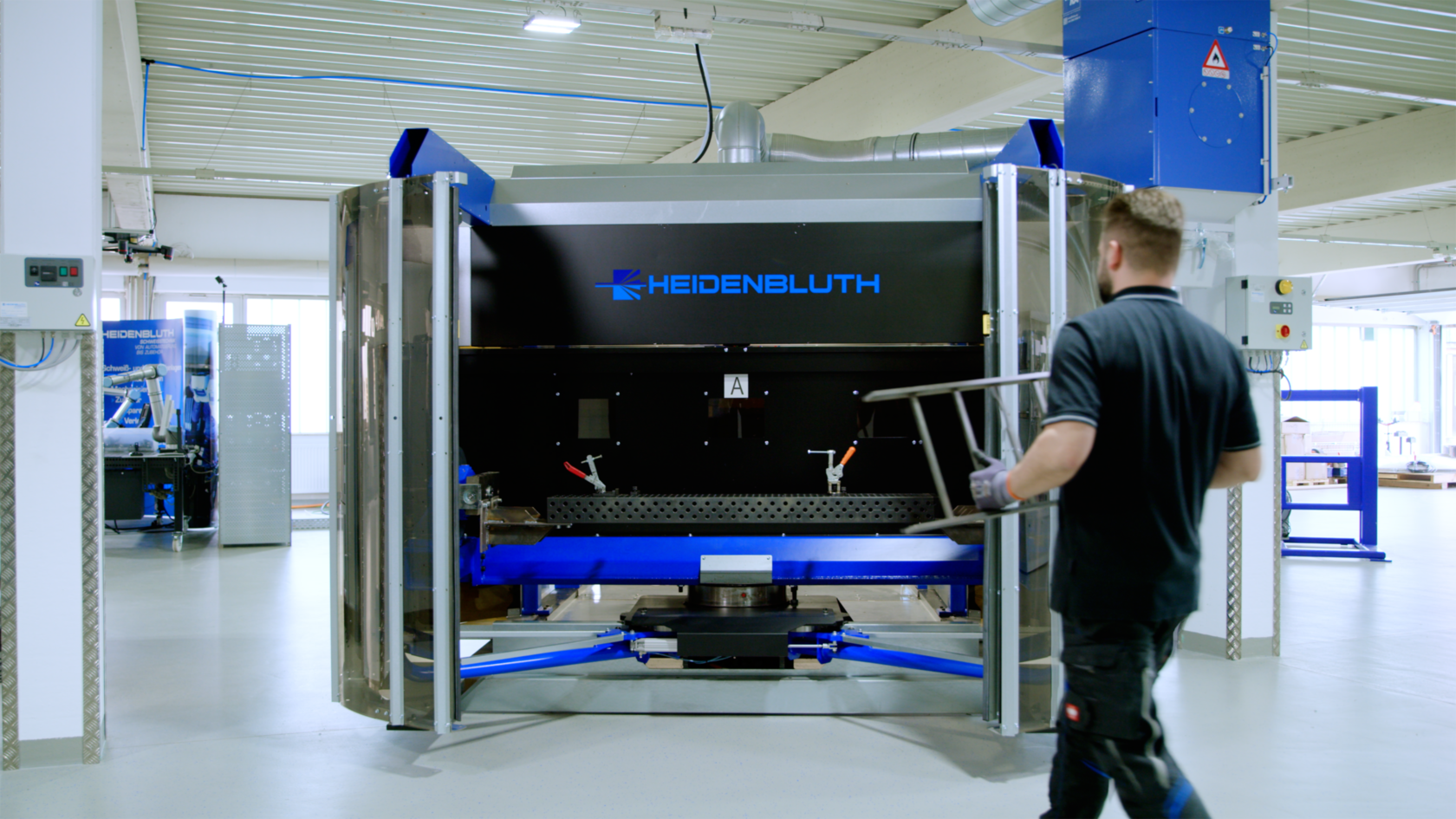

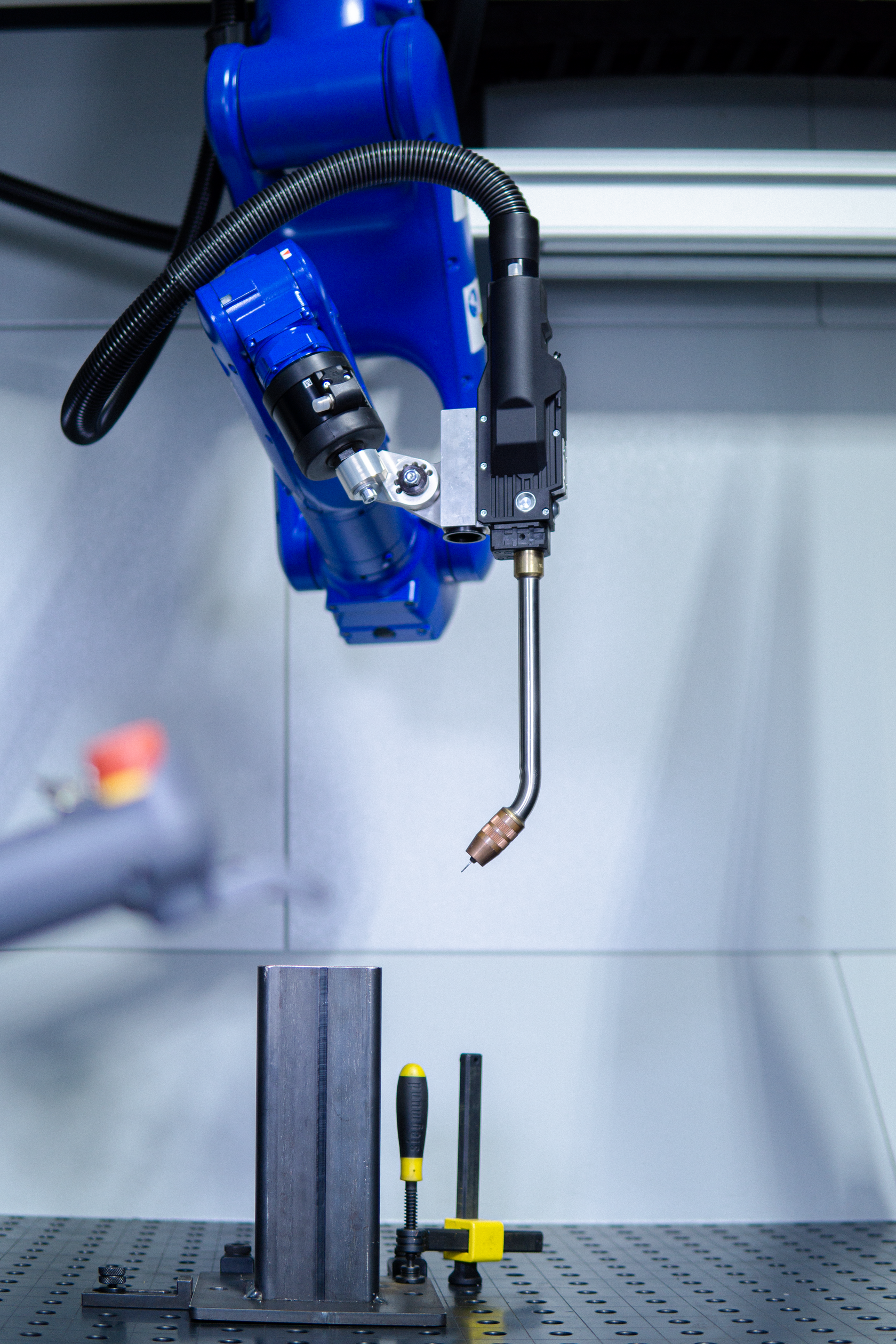

Yaskawa welding robot cells: Efficiency and precision in welding automation

Welding robot cells, especially those from established suppliers like Yaskawa, are essential tools for companies seeking to increase productivity and precision in industrial manufacturing. They offer an efficient solution for automating the welding process, and their advanced technology significantly improves the quality and consistency of welds. Below, we examine the features and benefits of Yaskawa's welding robot cells, which are considered pioneering in the industry.

In a time when companies are seeking efficient and cost-effective production solutions, Yaskawa 's welding robot cells offer a compelling option. They combine state-of-the-art technology with high quality and flexibility, adapting to the specific requirements of diverse industries. For companies that want to invest in their future and optimize their production processes, Yaskawa's welding robots represent a forward-looking solution.

By implementing Yaskawa welding robot cells, companies can strengthen their competitiveness and achieve a new era of productivity and precision in manufacturing through the integration of advanced robot technology.

-

Downloads

Heidenbluth Automationsbroschüre EN 2025

Advantages of automated welding systems

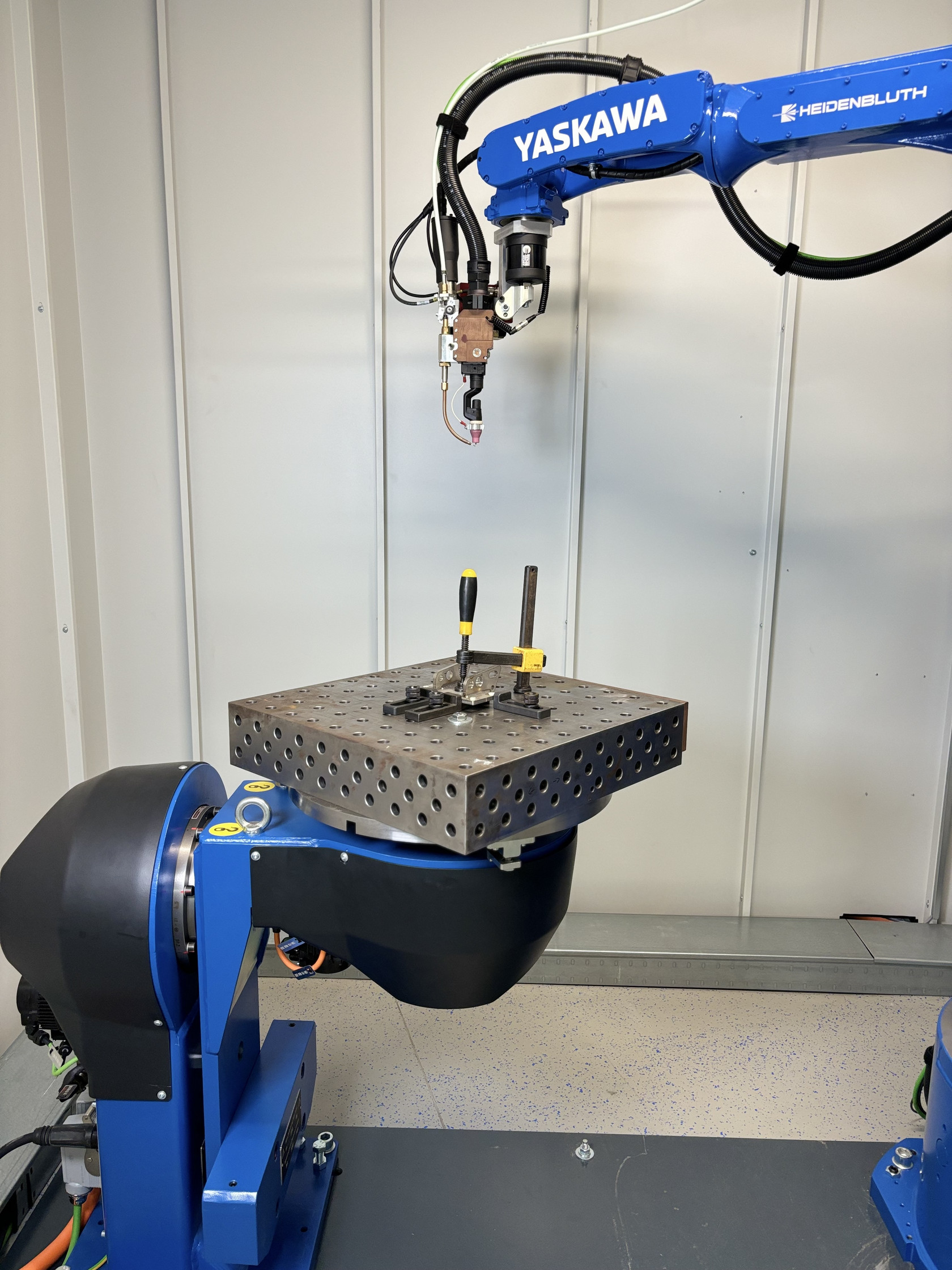

Switching to automated welding systems like those from Yaskawa offers companies numerous advantages. Besides a significant increase in productivity, the use of robotic cells also leads to a substantial reduction in the error rate, which not only lowers scrap and material costs but also increases customer satisfaction. In addition, Yaskawa's welding robots contribute to improved workplace safety by taking over hazardous welding tasks and thus minimizing the risk to employees.

Another advantage is the sustainable energy and resource efficiency . The precise control of the robot arms allows for the targeted use of welding materials, which reduces material consumption and protects the environment.

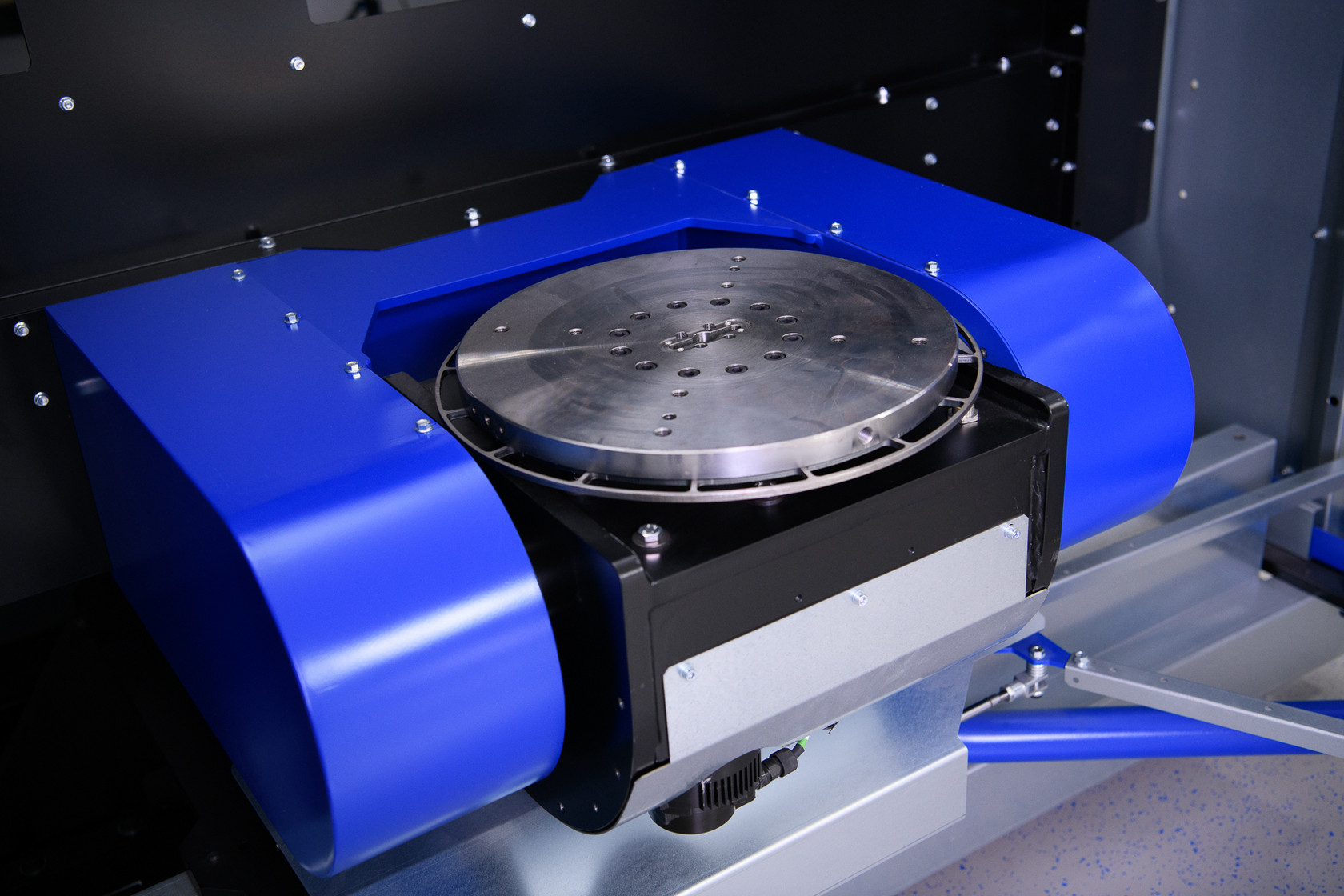

Quality and precision of Yaskawa welding robot cells

Yaskawa has been developing robotic solutions for decades and is particularly renowned in the field of welding technology for its high standards and innovations. Yaskawa's robotic cells are designed to meet all the key requirements for industrial welding applications. By utilizing state-of-the-art control and sensor technologies, Yaskawa welding robots ensure consistently high precision and speed. This leads to improved quality and a minimization of errors, which is especially advantageous in series production.

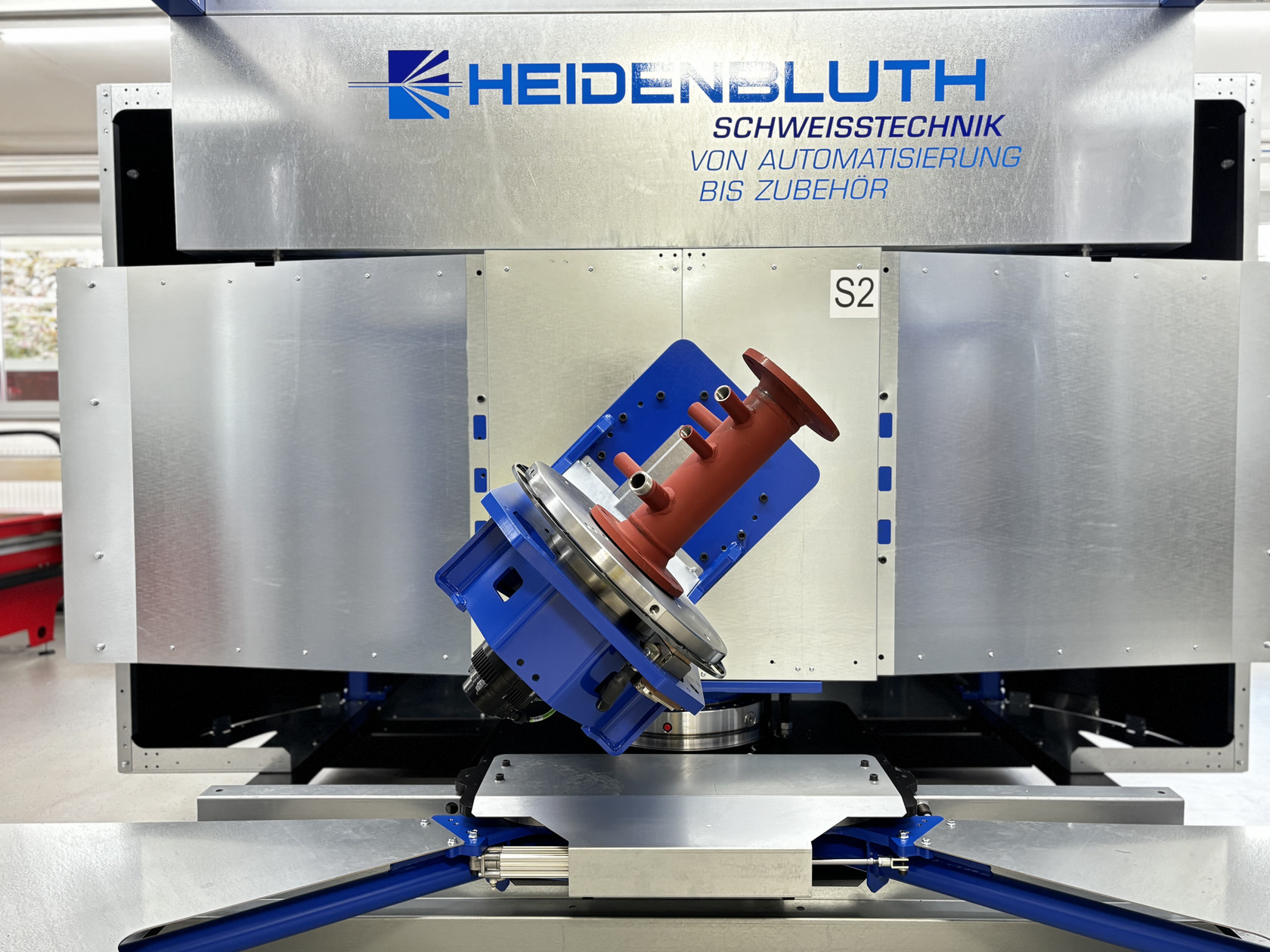

The Yaskawa welding robot cells are characterized by various features:

- Flexibility and adaptability:

The robot cells can be easily adapted to different workpiece sizes and shapes. - High efficiency:

Automation ensures faster welding processes and significantly reduces production time. - Increased safety:

Special safety precautions and sensors protect employees and ensure a safe workflow. - User-friendly control:

Yaskawa's user-friendly software makes it easy to create and modify robot programs, reducing setup time.

Application areas of welding robot cells

Yaskawa welding robot cells are used in a wide variety of industries, including automotive manufacturing , metal processing , heavy industry , and furniture production . Thanks to their high degree of flexibility, these welding robot cells can perform virtually all common welding processes, such as MIG, MAG, and TIG welding , precisely and efficiently. This makes them a valuable investment for companies that rely on consistent quality and efficiency.