![[Translate to English:] Anwendungszentrum Heidenbluth, Fachhandel für Schweißtechnik [Translate to English:] Anwendungszentrum Heidenbluth, Fachhandel für Schweißtechnik](/fileadmin/_processed_/b/6/csm_Heidenbluth_2022_084_low_ab8e87b4be.jpg)

Automated laser welding – efficiency and precision in modern welding technology

Automated laser welding is becoming increasingly important in industrial and craft manufacturing . This high-precision technology combines the advantages of laser radiation with automation technology and offers a particularly efficient and economical solution for numerous welding applications.

How does laser welding work?

Laser welding uses a high-intensity laser beam to precisely fuse materials. The laser enables concentrated heat input, allowing for narrow, deep, and extremely strong welds. This technology is frequently used, particularly in the automotive industry, mechanical engineering, metal construction, and aerospace .

Advantages of automated laser welding

Combining laser welding with robotic systems or cobot solutions makes it even more efficient. Automated systems take over repetitive welding tasks with high precision and repeatability. This offers numerous advantages:

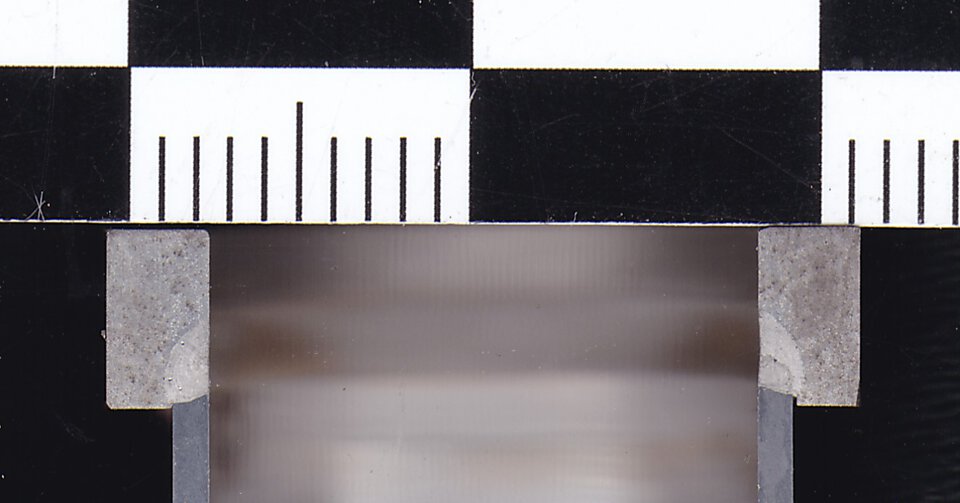

- Maximum precision: The focused laser beam enables extremely narrow weld seams with a minimal heat-affected zone, which reduces distortion.

- High welding speed: Automated control and fast laser processing significantly increase productivity.

- Flexibility: Laser welding systems can be individually adapted for different materials and components.

- Minimal post-processing: Clean welds reduce the need for grinding or polishing.

- Automated quality assurance: Integrated sensors and camera systems monitor the process in real time to ensure the highest quality.

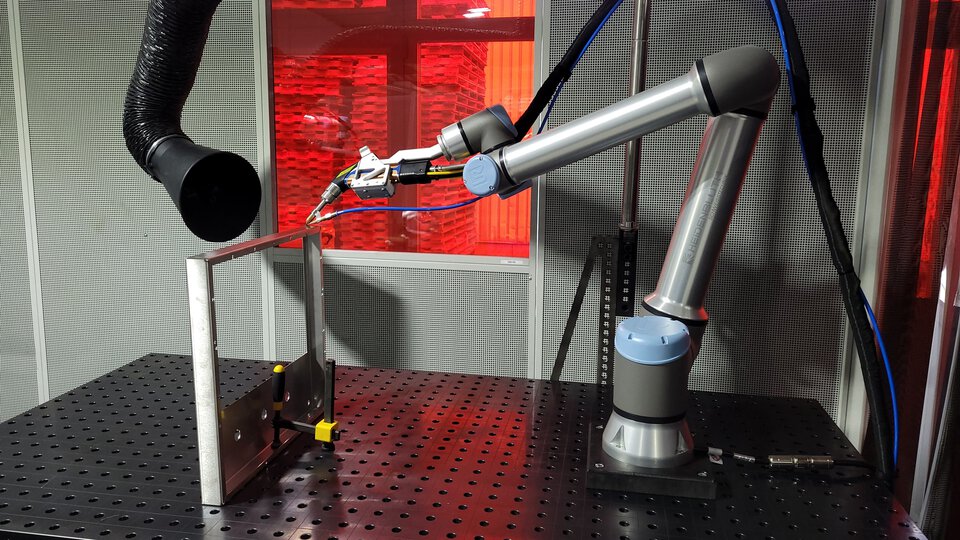

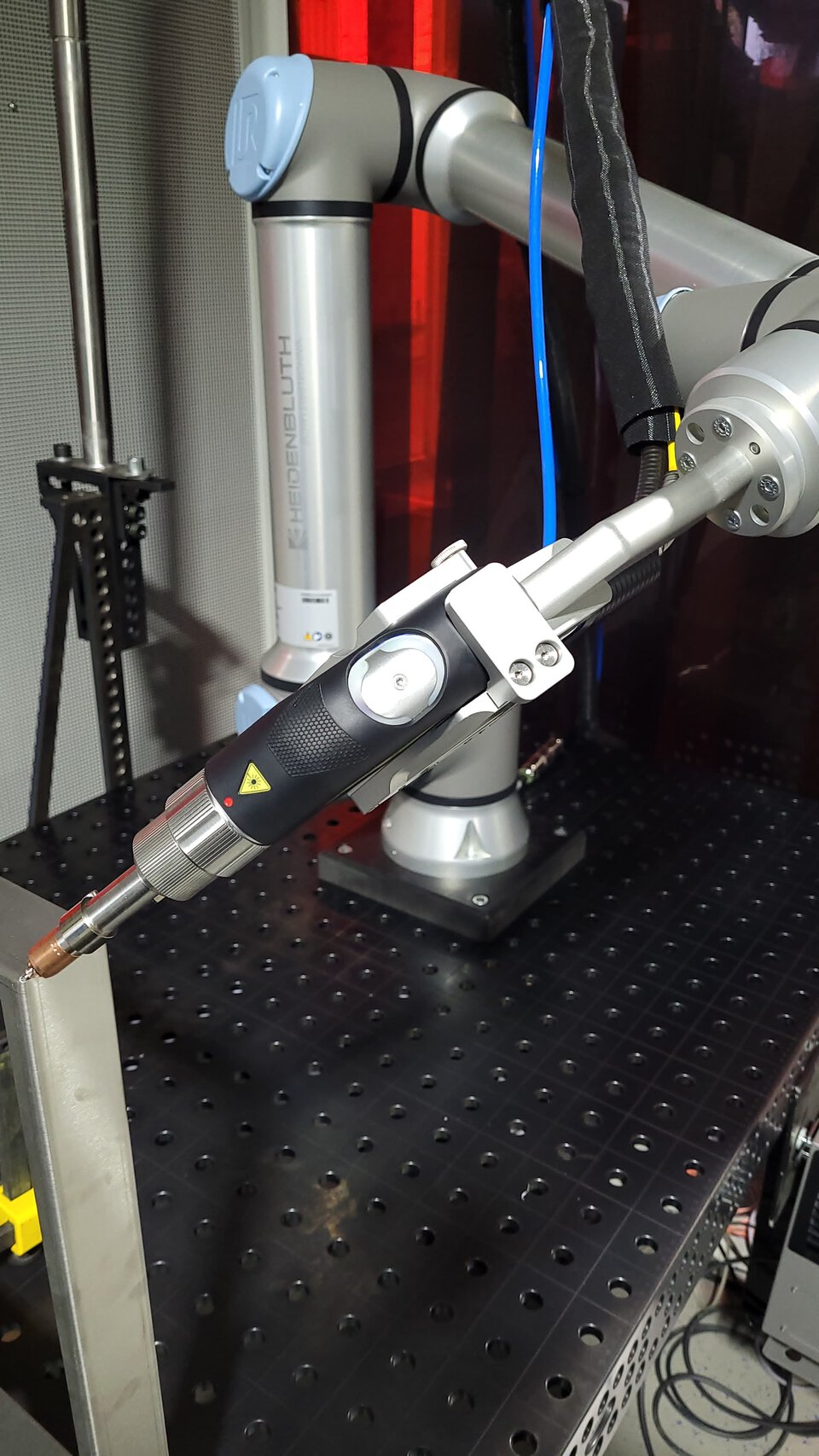

Laser welding with cobot support

With the increasing use of cobots (collaborative robots), laser welding is becoming even more flexible. Cobots are easy to program and can be used directly alongside humans, opening up new possibilities for small and medium-sized enterprises. Plug & play solutions enable rapid integration into existing production lines – without time-consuming training or complex programming.

Conclusion: The future of welding technology

Automated laser welding is revolutionizing welding technology through increased efficiency, quality, and process reliability. Companies that adopt this technology benefit from higher productivity, reduced costs, and consistently high quality – a crucial competitive advantage in modern industry.