Accessories for welding torches

To increase system availability and prevent malfunctions, various systems are available. Torch cleaning stations clean MIG/MAG torches by milling the gas nozzle to remove weld spatter and, if desired, subsequently reconditioning them with a spray.

Contact nozzle changers work similarly, but can additionally replace the worn contact nozzle fully automatically. Tungsten needle changers replace the tungsten needle fully automatically. The needle length is also automatically readjusted in the process, ensuring optimal TCP at all times.

Torch change systems allow for the replacement of the entire hose assembly or individual torch necks. During a torch neck change, the used torch neck is placed in a storage tray, pneumatically locked, and a new torch neck is inserted. This occurs during the ongoing process. The used torch neck can then be serviced with the usual care at a workstation and subsequently secured in the magazine. This is possible with both MIG/MAG and TIG equipment. Furthermore, it is possible to switch between TIG, MIG/MAG, and stud welding processes during the manufacturing process. This allows for the use of different welding processes on a single component or, more generally, enables the robotic system to perform various welding tasks. The desired tool is entered into the robot program, so the changeover occurs automatically. This also allows for switching between two different welding consumables without requiring any retooling by the operator.

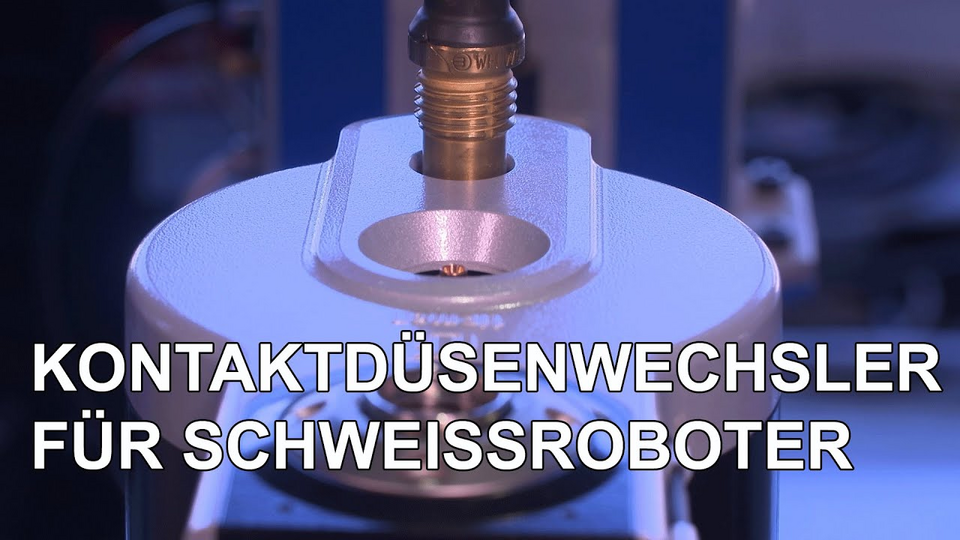

CONTACT NOZZLE CHANGER

The contact nozzle changer enables the robot to change its contact nozzles independently and fully automatically at a predefined interval.

Integrated gas nozzle cleaners and wire cutters further reduce downtime and eliminate potential damage caused by incorrect assembly.

AUTOMATIC TUBER NEEDLE CHANGE SYSTEM

The automatic tungsten needle exchange system consists of a robotic hose assembly and a tungsten needle exchange unit. This system was developed for use on a hollow-shaft robot. This reduces the hose assembly's obstructions and improves accessibility.

Furthermore, the optimized wire feed has been significantly improved, as it now runs linearly. In addition, there is an automatic tungsten needle exchange system. The robot carefully deposits the used tungsten needle and is automatically fitted with a new one. The needle length is then adjusted to the robot's TCP (Torque Transfer Controller), and the manufacturing process can continue. All of this happens without operator intervention, and the needle length is always correctly tensioned.

Tool changer

Stud welding on a robot (Yaskawa).

With automatic tool changer for two processes.