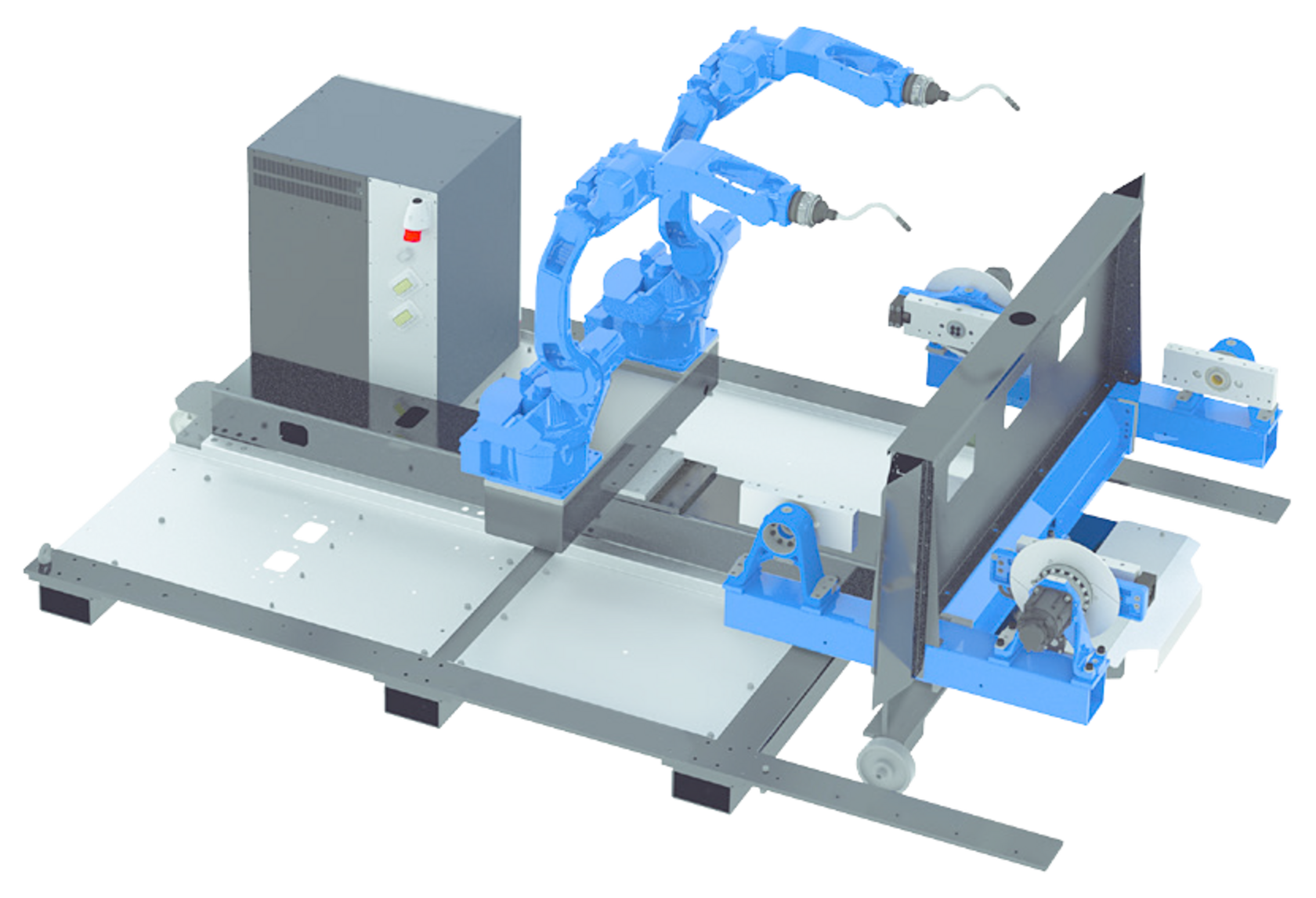

The ArcWorld V2 H is a modern and powerful solution in the field of robotic welding systems, optimized for a wide range of industrial applications.

This system is characterized by its configuration with a horizontal rotary axis integrated into each of the two stations.

The integration of these rotary axes enables precise and flexible welding processing, which is essential especially for complex and large-format workpieces.

![[Translate to English:] Heidenbluth - ArcWorld V2 H [Translate to English:] Heidenbluth - ArcWorld V2 H](/fileadmin/_processed_/f/6/csm_ARC_WORLD_II_1_5b82069eb6.png)

- 1

One horizontal rotary axis at each station

- 2

2 stations – robotic welding system

- 3

This system can be operated with one or two robots.

- 4

The system is forklift compatible.

- Two-station system : Working in parallel at two stations increases efficiency and throughput.

- Horizontal rotary axis at each station : Optimal workpiece positioning for precise welding.

- Flexibility in robot deployment : Can be operated with one or two robots, depending on production requirements.

- Forklift compatibility : Easy relocation by forklift enables high mobility.

- Compact design : Space-saving design fits well into various manufacturing environments.

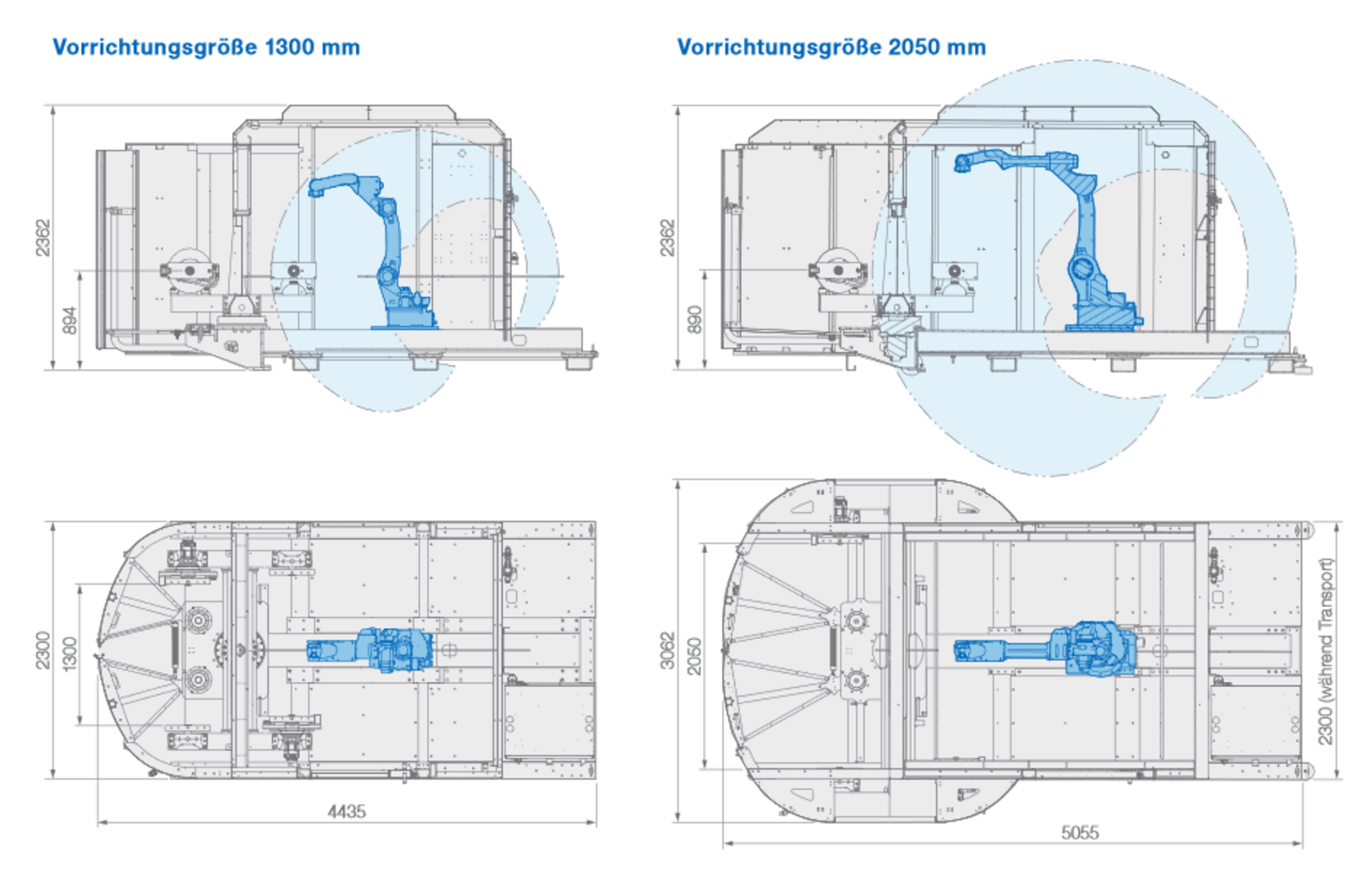

- Adaptability for different workpiece sizes : Center distance of 2,000 mm or 2,400 mm.

- Increased productivity : Parallel operation of two robots optimizes capacity utilization.

- System configuration : 2-station robot welding system

- Rotation axes : Horizontal rotation axis at each station

- Center distance : Optionally 2,000 mm or 2,400 mm

- Robot operation : Operation with one or two robots is possible.

- Forklift compatible : Yes, mobile and flexibly positionable

- Areas of application : Automotive industry, mechanical engineering, metal processing

- Application : Designed for complex welding tasks and large workpieces

- MIG/MAG from EWM

- MIG/MAG from Fronius

- CMT - Cold Metal Transfer by Fronius

- WIG-DC from EWM

- EWM TIG AC/DC

- TIG DC with cold wire feed from EWM

- TIG AC/DC with cold wire feed from EWM

- stud welding technology

- Siegmund base frame 2,000 mm

- Pneumatic zero-point clamping system for holding Siegmund interchangeable plates

- Automatic tungsten electrode changer

- Automatic contact nozzle changer

![[Translate to English:] Heidenbluth - ArcWorld V2 H [Translate to English:] Heidenbluth - ArcWorld V2 H](/fileadmin/_processed_/5/6/csm_ArcWorld2_3_f042fb4cfa.png)

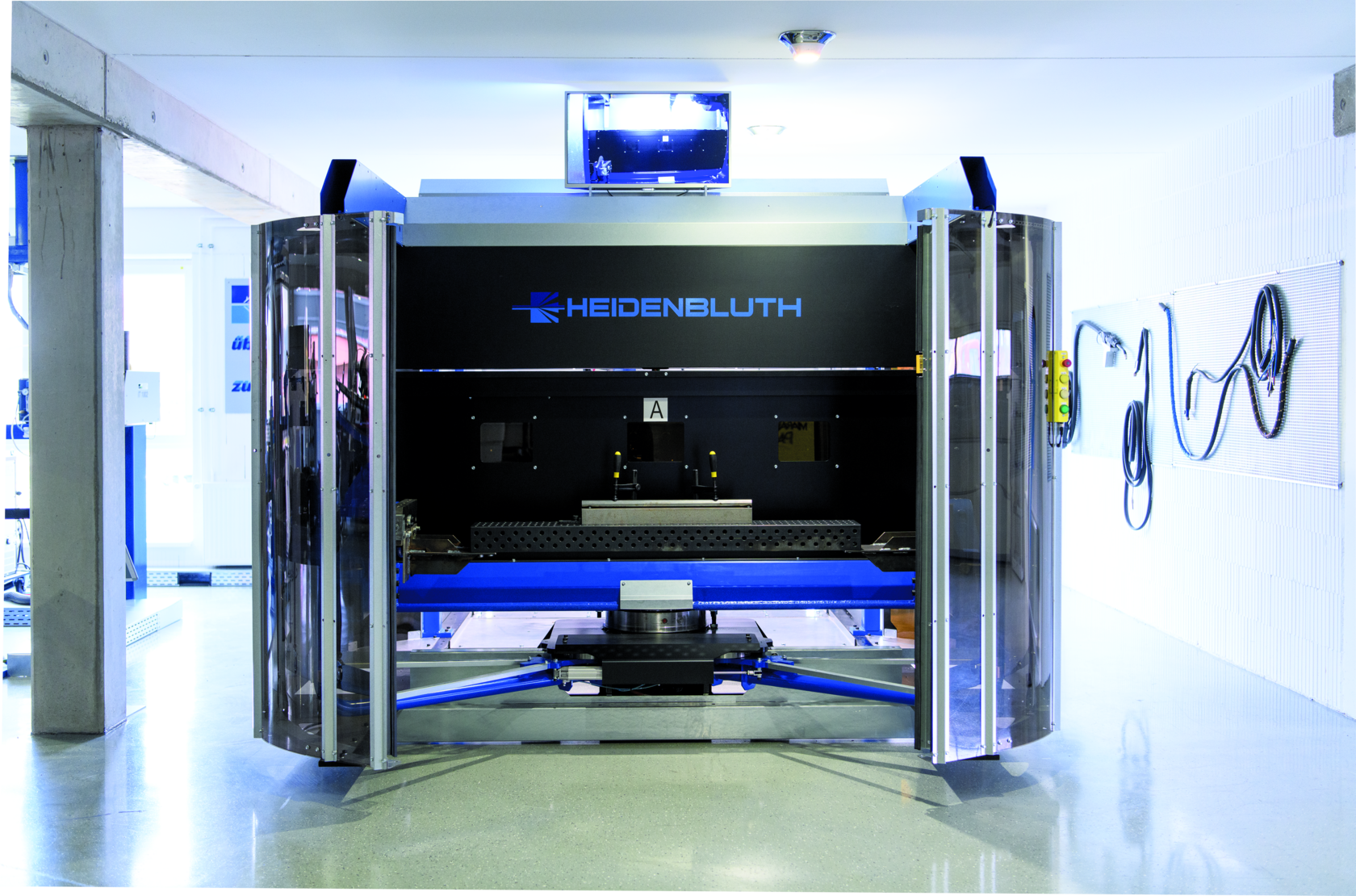

Flexibility: Operation with one or two robots

A special feature of the ArcWorld V2 H is its operational flexibility. The system can be equipped with either one or two robots, which increases efficiency and adaptability.

- Single-robot operation:

This configuration is particularly suitable for companies with low to medium production volumes or where the parts require more complex welds and higher precision. In this configuration, one robot performs the welding at both stations by moving back and forth between them. - Dual-robot operation:

In this configuration, each station is equipped with its own robot, allowing both stations to be used simultaneously. This is ideal for high-throughput production environments, as work can be carried out at both stations in parallel. This configuration saves time and significantly increases productivity by minimizing robot downtime.

![[Translate to English:] Heidenbluth - ArcWorld V2 H [Translate to English:] Heidenbluth - ArcWorld V2 H](/fileadmin/_processed_/c/c/csm_ArcWorld2_31_0fe1d066d2.png)

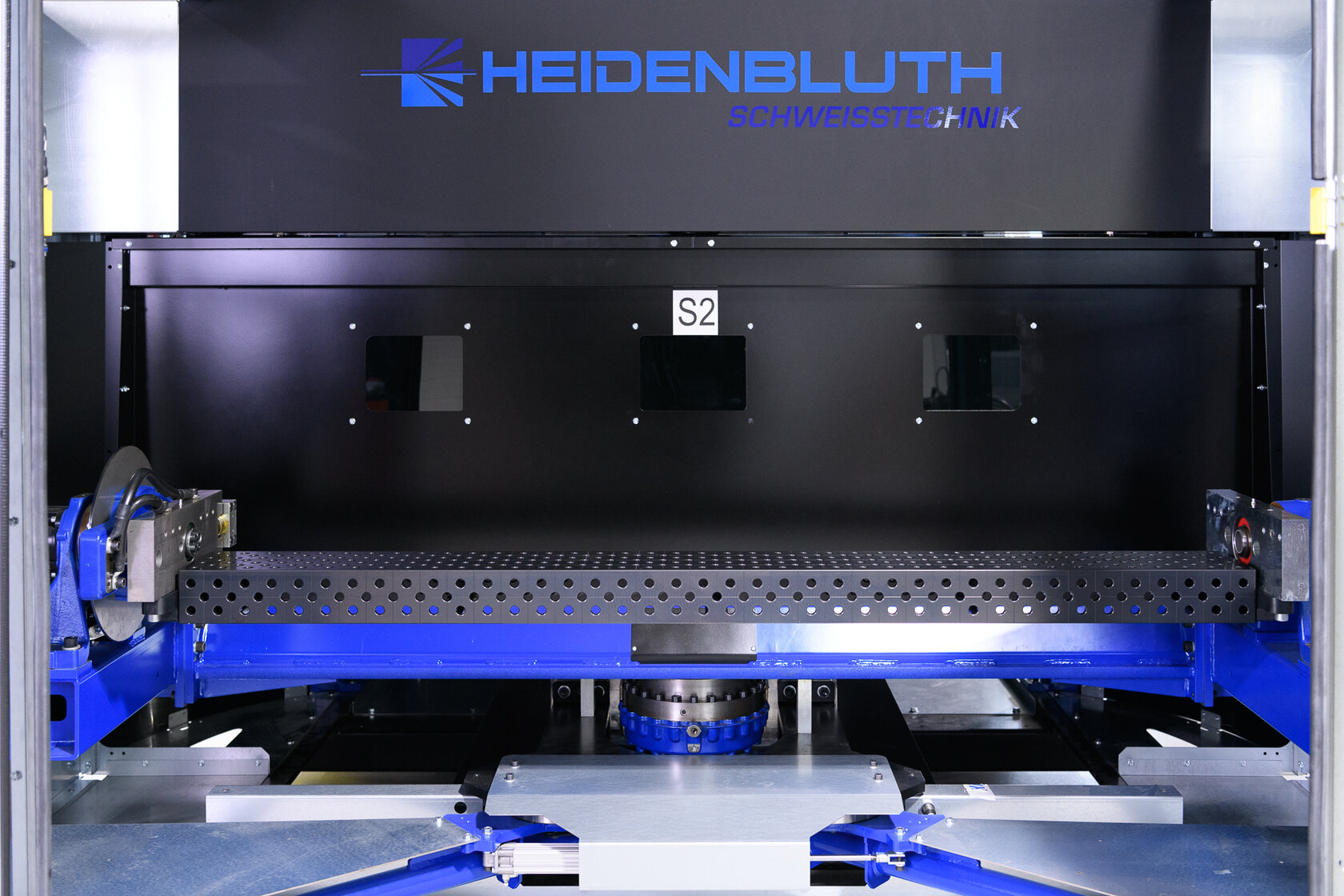

Applications and areas of use

The ArcWorld V2 H is capable of performing demanding welding tasks efficiently and precisely, making it suitable for a wide range of industrial applications. Typical areas of application include the automotive industry, mechanical and plant engineering, and the production of metal components, where high precision and productivity are required.

The ArcWorld V2 H truly shines when manufacturing components that require large spans and precise welds. Its ability to operate with either one or two robots makes it suitable for companies with varying production needs and volumes. Smaller companies benefit from the efficiency and precision of single-robot operation, while large production lines can maximize their output with two robots.

![[Translate to English:] Heidenbluth ArcWorld V2 H](/fileadmin/_processed_/c/4/csm_HEIDENBLUTH_SCHWEISSROBOTER_ARC_WORLD_V2_f1d1686057.png)