Weld seam search

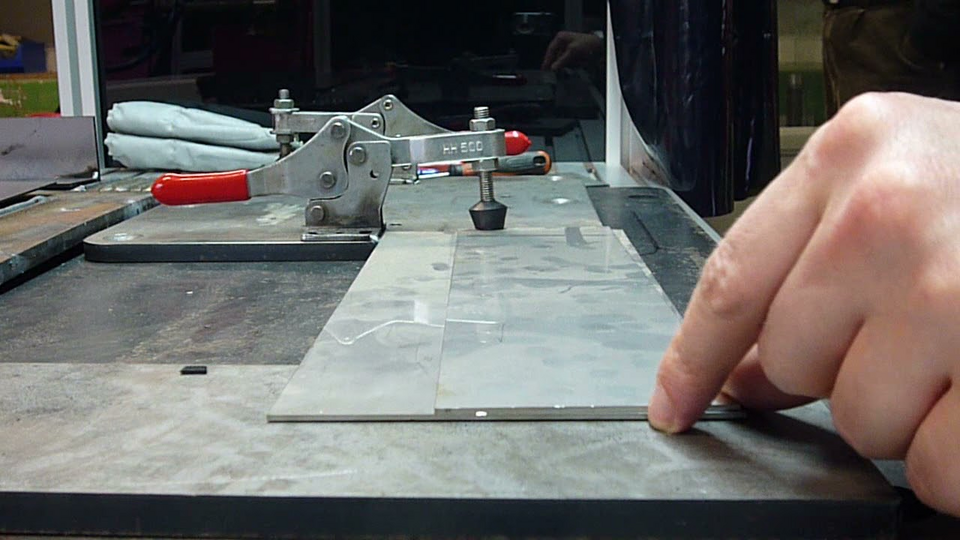

TOUCH SENSE

Tactile searching via the wire end or the gas nozzle.

Touch Sense uses the free wire end or the gas nozzle to scan the position of the component. The robot's program is then automatically corrected, ensuring a reliable welding process.

SEAM TRACKING

Seam tracking via voltage monitoring.

Seam tracking, or automatic seam tracking, is also possible for fillet welds using arc voltage. The robot's oscillating motion utilizes the arc length to determine the root point. This allows for automatic adjustment of the travel paths in case of component distortion or tolerances during the welding process.

WIRE SENSE

Suture detection via pulsating wire

Wire Sense is also known as wire detection. Through a high-frequency forward and backward movement of the wire, the component is detected, and component position errors are automatically corrected.

WELD SEAM DETECTION CAMERA

Our weld seam cameras support your robots in weld seam finding and weld seam tracking.

These compact cameras, optimized specifically for welding and cutting, are characterized by high speed and accuracy. We would be happy to assist you in selecting the right camera system and explain the advantages of arc seam tracking.

WELD SEAM TRACES CAMERA

This camera system makes it possible to monitor and correct the weld seam live during welding.

This allows, among other things, a response to component distortions during welding.