Welding robots for medium-sized businesses: Efficient, flexible and future-proof

In times of skilled labor shortages and increasing demands for precision and efficiency, the use of welding robots is no longer just relevant for large corporations. Small and medium-sized enterprises (SMEs) are also increasingly benefiting from the advantages of welding automation. Modern welding robots offer SMEs the opportunity to produce cost-effectively and flexibly without compromising on quality.

Welding robots for diverse applications

Automated systems are of interest to companies when they face the challenge of performing recurring tasks with any frequency and consistently high quality. This is precisely where welding robots demonstrate their strengths.

At Heidenbluth, we advise you on which welding robot is right for you. In addition to the classic 6-axis welding robots from Yaskawa, we also offer a wide range of cobot welding solutions. For almost 50 years, we have been much more than a first-class automation partner for our customers. We are your contact persons, problem solvers, researchers, developers, express delivery specialists, trainers, or even just someone to chat with over a cup of coffee in our application center.

-

Downloads

Automation brochure

Universal Robot VS Yaskawa

Which robot is right for your company?

In the world of welding automation, the question is more relevant than ever: Which robot is the right one? Cobots, such as the flexible UR10 from Universal Robots, and classic industrial robots, such as the high-precision MA1440 from Yaskawa, offer two different approaches to automation – each with its own strengths and advantages.

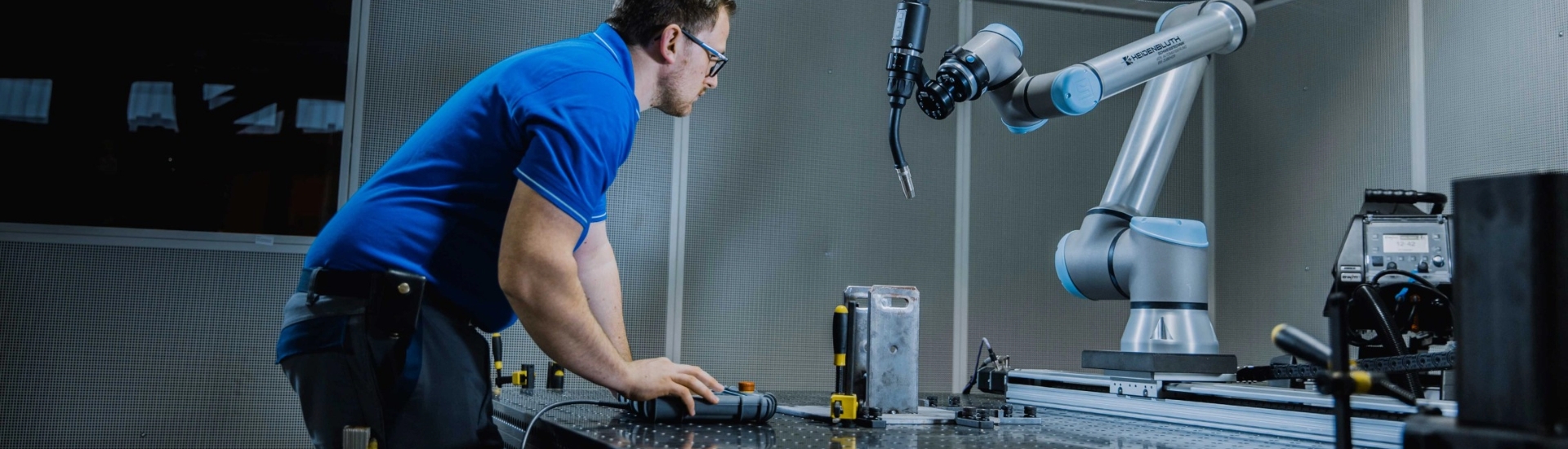

Cobots have taken the market by storm in recent years, offering small and medium-sized enterprises (SMEs) an exciting opportunity to enter the world of robotics. Thanks to their compact design and collaborative safety technology, they can be easily integrated into existing work environments and often even operate directly alongside employees. Ideal for companies with fluctuating workloads, cobots can be quickly reconfigured, making them particularly suitable for applications requiring flexibility and adaptability.

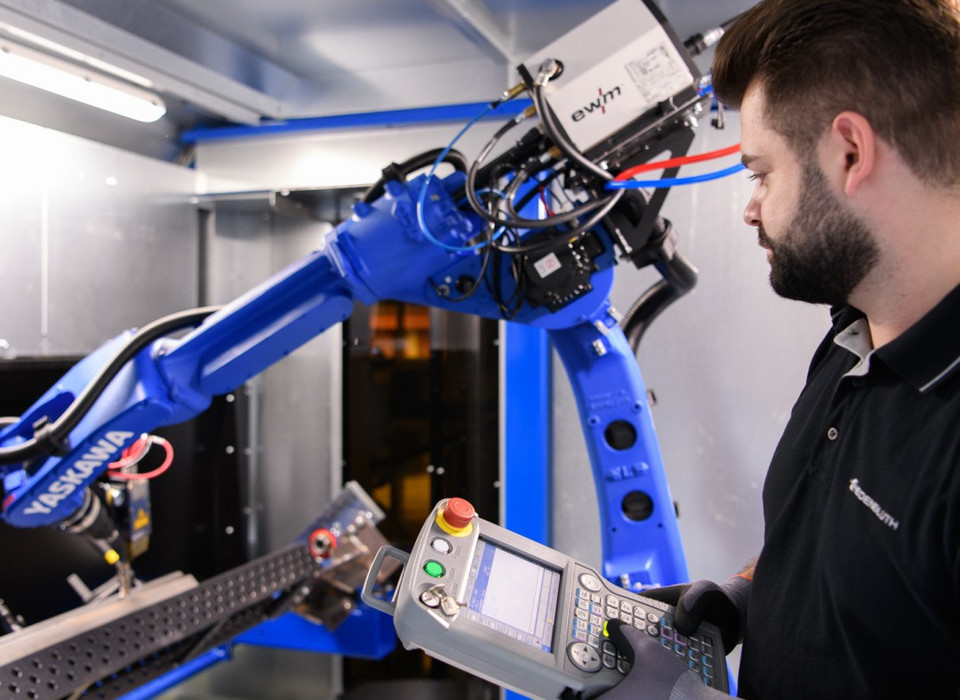

On the other hand, classic industrial robots like the Yaskawa MA1440 offer unparalleled precision and robustness. These robots are designed to operate reliably in the most demanding welding processes and in continuous three-shift operation. Thanks to their speed and repeatability, they are the optimal choice when it comes to high production volumes and complex welding tasks where no compromises on quality can be made.

At Heidenbluth, we understand that every production process is unique. That's why we offer independent consulting to find the perfect robot to meet your specific requirements and circumstances. In our application center, you can experience our cobots and industrial robots firsthand and gain a clear understanding of the technology and its capabilities. This provides you with a solid foundation for selecting the right solution for your automation strategy.

Getting started with automation using the cobot from Universal Robots

Since its founding in 2005, Universal Robots has revolutionized the world of automation – with one clear goal: to make robotics technology accessible to small and medium-sized enterprises (SMEs). What began as a vision is now a reality. With cobots that are safe, flexible, and intuitive to operate, Universal Robots offers the perfect entry point into automation for companies of all sizes.

The UR10e and UR5e models are known worldwide as high-performance all-rounders. These cobots have established themselves as indispensable assistants in automated manufacturing and master a wide range of tasks – from welding to material handling. With their precise control, user-friendly programming, and ability to work hand in hand with humans, they help companies make their production more efficient and flexible.

For companies looking to take their first steps into automation, Universal Robots' cobots offer a future-proof solution: They reduce production costs, increase quality, and can be easily integrated into existing processes. Universal Robots is setting new standards and making access to robotics technology easier than ever before – for companies that want to remain competitive and grow.

Yaskawa welding robots: Precision and process reliability at the highest level

Yaskawa, the leading Japanese technology company with more than 430,000 robots installed worldwide, stands for pioneering innovation and reliability in automation technology. Yaskawa has been our premium partner for over 15 years, and together we are setting new standards for welding processes, maximizing precision and process reliability.

Our Yaskawa welding robots are used where the demands for complexity and quality exceed the capabilities of cobots. Whether it's difficult angles, inaccessible areas, or extremely high precision requirements – Yaskawa robots master even the most demanding tasks reliably and efficiently.

At our modern application center in Fuldabrück near Kassel, we offer a wide range of Yaskawa robots and welding cells available for individual welding trials. Here, customers can test the robots' performance under realistic conditions and have customized solutions developed that precisely match their specific requirements.

In addition to proven standard cells, we also develop tailored, customer-specific automation concepts that enable companies to achieve maximum flexibility and efficiency in their welding processes. With Yaskawa welding robots, we offer a solution designed to meet the highest demands – ideal for those who refuse to compromise on welding quality.

Experience welding robots up close: development, testing, and real-world applications

Immerse yourself in the world of welding automation and experience our robot technology in action! Under the motto "Develop, test, experience live," we cordially invite you to get to know our expertise and capabilities firsthand. In our application center, you'll see how welding robots can optimize your production processes in real time – efficiently, precisely, and with future-proof technology.

Be impressed by the quality and performance of our systems and discover how automation can sustainably increase efficiency in your operations. Together with you, we will develop tailored solutions that optimally support your business and have a direct, positive impact on your production goals. We look forward to getting to know you and your requirements and unlocking the decisive advantages of automation for your company.