The ArcWorld EVO is particularly suitable for complex welding tasks.

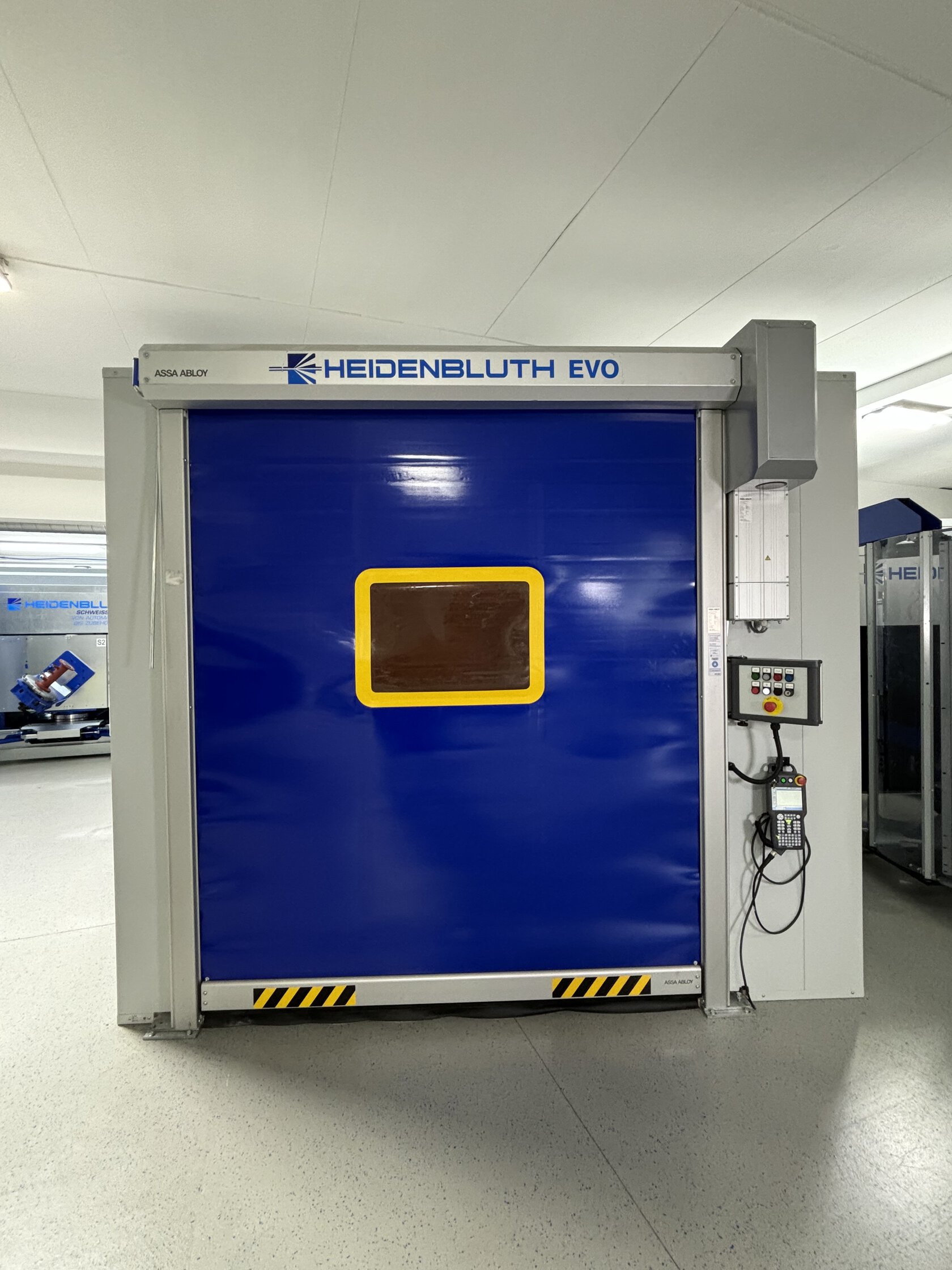

The existing positioning technology, using a rotary tilting table, allows even demanding welding tasks to be completed safely and quickly. The front of the robot cell is equipped with a roller door.

Inside the cell is a six-axis Yaskawa MA2010 industrial robot. The system naturally has a CE declaration of conformity.

- 1

High-speed door with viewing window

- 2

Yaskawa hollow shaft industrial robot for 360° welding without a shoulder, with extensive additional functions

- 3

Rotary tilting table for optimal component positioning

- 4

ArcWorld Evo Robust control panel

- Short delivery time

- The rotary tilting table allows for the welding of complex components.

- Easy installation of the system

- Generous insertion area

- Prepared for offline programming

- CE Declaration of Conformity for the entire system

- CE Declaration of Conformity for the entire system

- Positioning technology using a rotary/tilting table

- MIG/MAG from EWM

- MIG/MAG from Fronius

- CMT - Cold Metal Transfer by Fronius

- WIG-DC from EWM

- EWM TIG AC/DC

- TIG DC with cold wire feed from EWM

- TIG AC/DC with cold wire feed from EWM

- stud welding technology

- Pneumatic zero-point clamping system for holding Siegmund interchangeable plates

- Siegmund Octagonal Table Plasma Nitrided

- Automatic tungsten electrode changer

- Automatic contact nozzle changer

The ArcWorld EVO – The solution for complex welding tasks

The ArcWorld EVO is a state-of-the-art welding robot cell specifically designed for demanding and complex welding tasks. Its flexible and precise positioning technology, supported by a rotary tilting table, makes it the ideal solution for a wide range of welding processes. The ArcWorld EVO proves itself a reliable workhorse, especially in manufacturing environments where high accuracy and efficiency are essential.