Individual welding trials for customized solutions in welding technology

Welding technology plays a crucial role in modern manufacturing. With the development of new materials and complex component geometries, precise and effective welding solutions are more in demand than ever.

Through individual welding trials, we offer tailored approaches to optimize the weldability of your specific materials and components. In this way, we support you in developing stable and efficient welding processes that are adapted to your individual requirements.

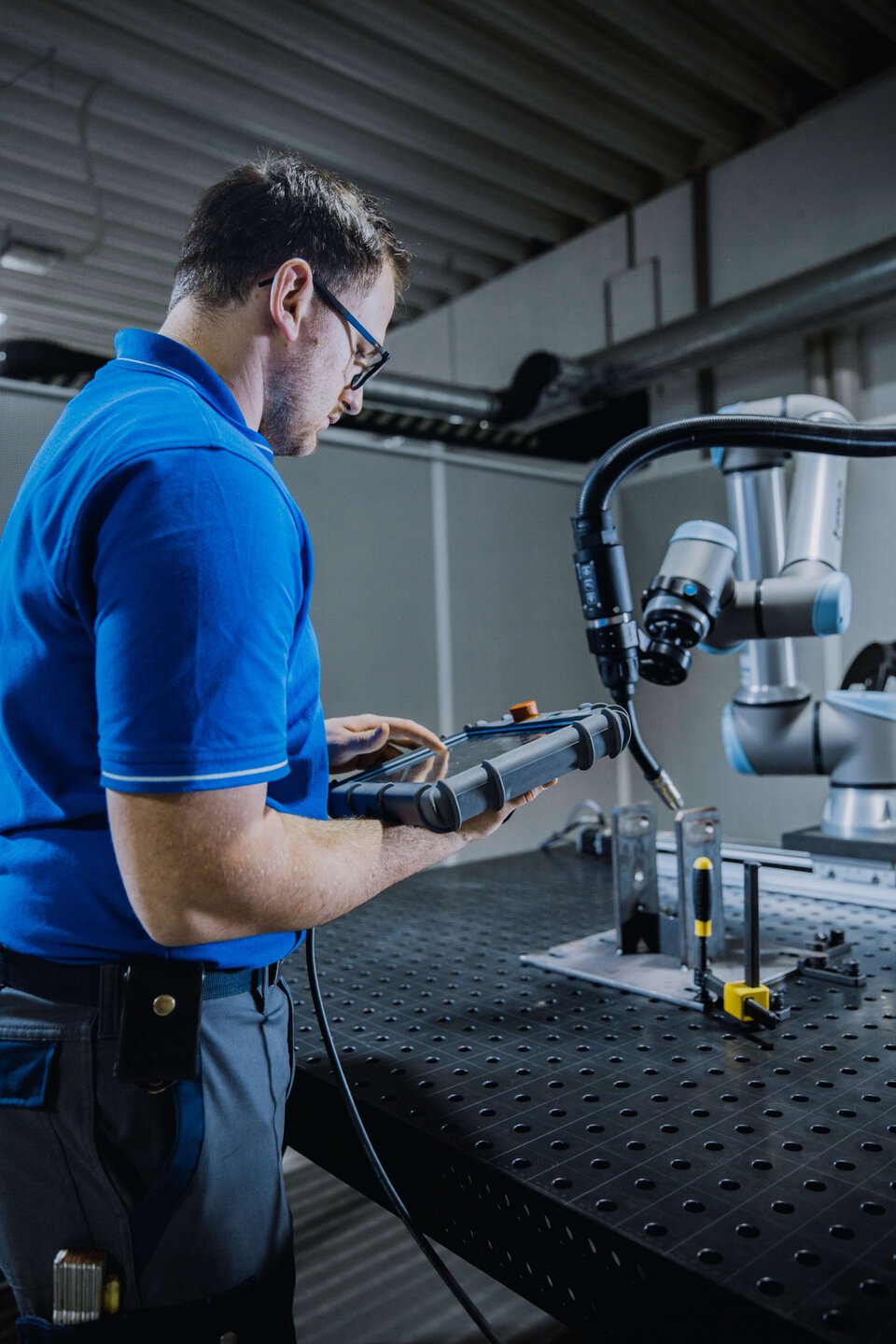

![[Translate to English:] Schweißversuche](/fileadmin/_processed_/9/a/csm_Schwei%C3%9Fversuch_39f7550b9d.jpg)

Advantages of individual welding trials

Whether it's about new base materials that require welding processes, or about optimized weld geometries: Our welding trials are specifically designed to find solutions that improve the production process. These include, among other things:

- Heat-reduced welding to minimize thermal deformations and material stresses.

- Welding of components with large gap dimensions for applications where manufacturing tolerances are important.

- Cold wire welding for applications where minimizing heat input is crucial.

Our expertise also includes welding aluminium and CrNi steels (chromium-nickel), which place special demands on the welding processes in order to maintain material properties and corrosion resistance.

Innovative welding processes to improve quality

Another challenge in modern welding technology is the reduction of spatter, which enables a smoother weld seam and a higher surface quality of the components. Significant quality improvements can be achieved with innovative welding methods and technologies, such as optimizing the weld opening angle.

Automating welding processes is also one of our specialties, increasing reproducibility and efficiency in production. Automated solutions in our modern automation center guarantee reliable and consistent welding quality, even with high production volumes.

Your partner for individual solutions and advice

Our individual welding trials are not just about creating a weld – we analyze in detail how your specific components and materials can best be welded.

Our experts work closely with you to develop ideal joining processes, even for particularly demanding materials such as high-strength materials . Together, we develop solutions that optimize your production processes and ensure the quality of your end products.