The Arc World XL H is a state-of-the-art, automated robotic welding system designed for industrial applications in the field of robotic welding.

This specific system is designed for efficiency, flexibility, and precision to meet the demands of modern production lines. With its two-station design and robust construction, it allows for seamless integration into various industrial environments where high-quality welded joints are required.

The Arc World XL H is a highly advanced robotic welding system distinguished by its flexibility, long range of motion, and the option of dual-robot operation. This system enables companies to automate their production lines, reduce labor costs, and maximize weld quality. The two-station configuration and horizontal rotary axes allow for precise and versatile workpiece machining, making the Arc World XL H a powerful solution for demanding manufacturing industries.

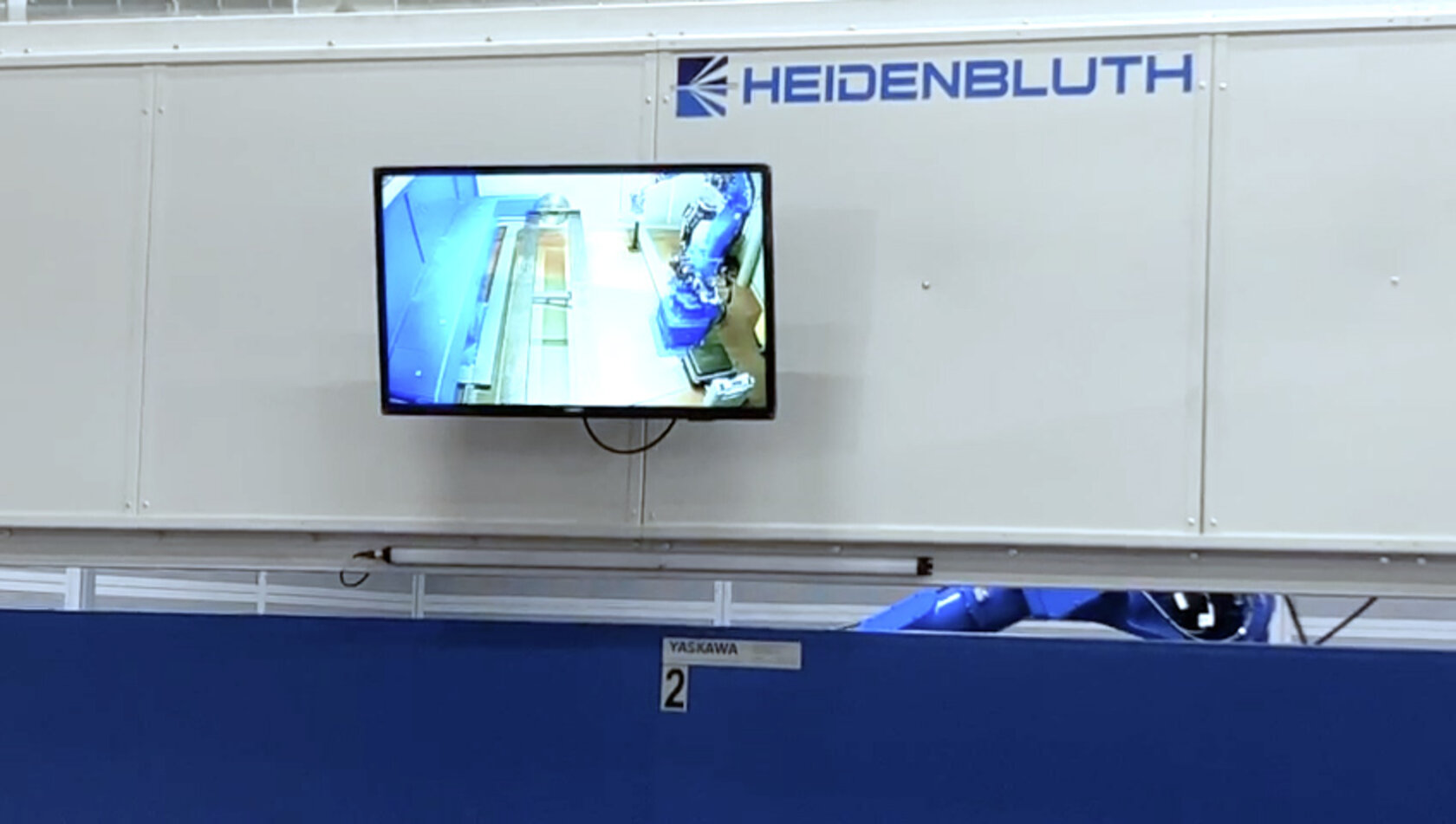

![[Translate to English:] Heidenbluth - ArcWorld XL H [Translate to English:] Heidenbluth - ArcWorld XL H](/fileadmin/_processed_/6/8/csm_ArcWorld_XL_H_8a2fde2c7b.png)

- 1

One horizontal rotary axis at each station

- 2

This system can be operated with one or optionally two robots.

- 3

The center distance is 3,000 mm.

- High productivity : Two stations and the possibility of two-robot operation maximize production capacity and reduce cycle times.

- Flexibility : Operation with one or two robots is possible, allowing adaptation to different production volumes and requirements.

- Space-saving design : Compact layout allows for easy integration into existing production lines.

- High welding quality : Automated robot operation ensures consistent and precise welds, which increases product quality and minimizes rework.

- Versatile welding positioning : Horizontal rotary axes at each station enable flexible welding positions for complex component geometries.

- Cost and time savings : Automation reduces labor costs and shortens lead times.

- Stations : 2

- Robot type : One or two welding robots (optional)

- Rotary axes : One horizontal rotary axis per station

- Center distance : 3,000 mm (enables welding of large workpieces)

- Operating mode : Flexibly adjustable for single or dual robot operation

- Typical application areas : automotive industry, mechanical engineering, heavy industry, aerospace

- Level of automation : Highly automated system for precise and fast welding.

- MIG/MAG from EWM

- MIG/MAG from Fronius

- CMT - Cold Metal Transfer by Fronius

- WIG-DC from EWM

- EWM TIG AC/DC

- TIG DC with cold wire feed from EWM

- TIG AC/DC with cold wire feed from EWM

- Stud welding technology

- Pneumatic zero-point clamping system for holding Siegmund interchangeable plates

- Siegmund base frame 3,000 mm

- Automatic tungsten electrode changer

- Automatic contact nozzle changer

Structure and features of the Arc World XL H

The Arc World XL H is designed as a two-station robotic welding system. This means it offers two separate workstations that can be operated independently. Each station is equipped with a horizontal rotary axis that positions workpieces optimally for welding, ensuring precise and consistent quality for complex welding tasks. The rotary axes enhance the system's flexibility by allowing for various welding positions and angles that can be precisely controlled by a single robot.

A key feature of the Arc World XL H is its maximum center distance of 3,000 mm. This enables the processing of even large and bulky workpieces, which are often required in industries such as automotive, mechanical engineering, and heavy industry. With this generous center distance, the machine is suitable not only for small workpieces but also for large components that would often be too unwieldy for manual handling.

Areas of application and future prospects

The Arc World XL H finds application in a wide range of industries, including automotive, aerospace, mechanical engineering, and heavy industry. Wherever high precision, large workpieces, and consistent weld quality are required, the Arc World XL H can demonstrate its strengths.

The option to operate the system with one or two robots also enhances its future-proofing. Companies that initially start with one robot can easily scale up production later by integrating a second. This makes the Arc World XL H a flexible solution for growing production needs and technological advancements.