Robotic Additive Manufacturing (WAAM) – Efficient 3D Printing of Metal Components

Robotic additive manufacturing (WAAM) is a modern 3D printing technology that has become established in numerous industries in recent years.

Warm additive manufacturing (WAAM – Wire Arc Additive Manufacturing), in particular, when combined with industrial robots, offers high flexibility, efficiency, and material utilization. The process is especially suitable for the production of large-format metal components and enables cost-effective, automated production with a high degree of design freedom.

Advantages of Additive Manufacturing with Robots

Robots in additive manufacturing offer exceptional flexibility because they can be quickly reprogrammed to efficiently implement various designs in 3D printing.

At the same time, they enable the production of highly complex geometries and structures that would be difficult to achieve with conventional methods such as milling. The layer-by-layer construction of additive manufacturing also significantly increases material efficiency, as material is used precisely and waste is minimized. Therefore, robots in additive manufacturing represent an innovative solution for producing customized, complex components efficiently, sustainably, and with minimal resource consumption.

How can such a project be implemented?

Implementing a project with robots in additive manufacturing differs significantly from traditional robotic manufacturing. Path planning and the numerous influences on the process, in particular, require greater attention to ensure precise and efficient production.

To successfully implement this for you, we work closely with two other specialized companies. Together, we can support your project from planning to implementation. Pro WAAM sees itself as a partner that supports you step by step on your journey to additive manufacturing and ensures that individual, complex components are manufactured efficiently and to a high standard.

Preparation of the component design

Die Vorbereitung des Bauteildesigns ist ein entscheidender Schritt in der additiven Fertigung und 3D-Drucktechnologie. Von der CAD-Modellierung über die Materialauswahl bis hin zur Roboterprogrammierung und dem eigentlichen Druckprozess muss jeder Schritt sorgfältig geplant werden, um eine präzise Geometrie, optimale Materialeigenschaften und hohe Oberflächenqualität zu gewährleisten. Eine systematische Nachbearbeitung sichert schließlich die Funktionalität und das gewünschte Finish des Bauteils. Durch die Kombination von digitalem Design, hochwertigen Werkstoffen und automatisierter Fertigung können komplexe Bauteile effizient und zuverlässig produziert werden.

3D modeling: First, a precise 3D model of the component is created using CAD software. This model serves as the basis for the entire manufacturing process.

Customize file format: The model is then converted into a printable format (e.g., STL or OBJ).

Suitable materials: For additive manufacturing, specially suitable materials such as metal alloys are used.

Material procurement: High-quality solid or flux-cored wires must be provided in the correct quality to ensure optimal printing results.

Determine movement sequences: The manufacturing robot is programmed to control precise positioning and speed during the printing process.

Define print path: Based on the CAD model and the material properties, the optimal path for material application is determined.

Material order: The material is applied in layers. Precise control of heat and cooling ensures uniform flow and precise geometry.

Cooling: After each layer, the material hardens while the robot prepares the next layer.

Surface processing: The finished component is sanded, painted or further treated to achieve the desired surface and material properties.

Advantages

Additive manufacturing with robots offers numerous advantages over conventional manufacturing methods. It enables the production of complex structures that reduce the weight of components while maintaining their functionality.

Furthermore, spare parts can be produced significantly faster, minimizing inventory after completion of series production. Manufacturing components with varying quality levels is also possible, allowing for the efficient implementation of individual requirements. In addition, additive manufacturing can replace milled parts or castings, thereby reducing costs and production times.

The process is known by various names, including 3D printing, additive manufacturing or the WAAM process (Wire Arc Additive Manufacturing), with all variants based on the principle of layer-by-layer material build-up to efficiently produce complex, high-quality components.

System Setup

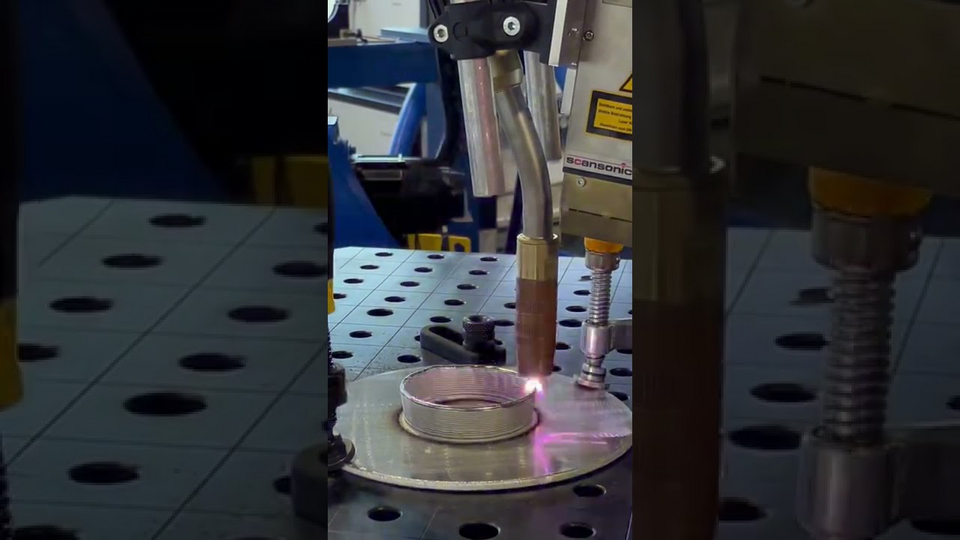

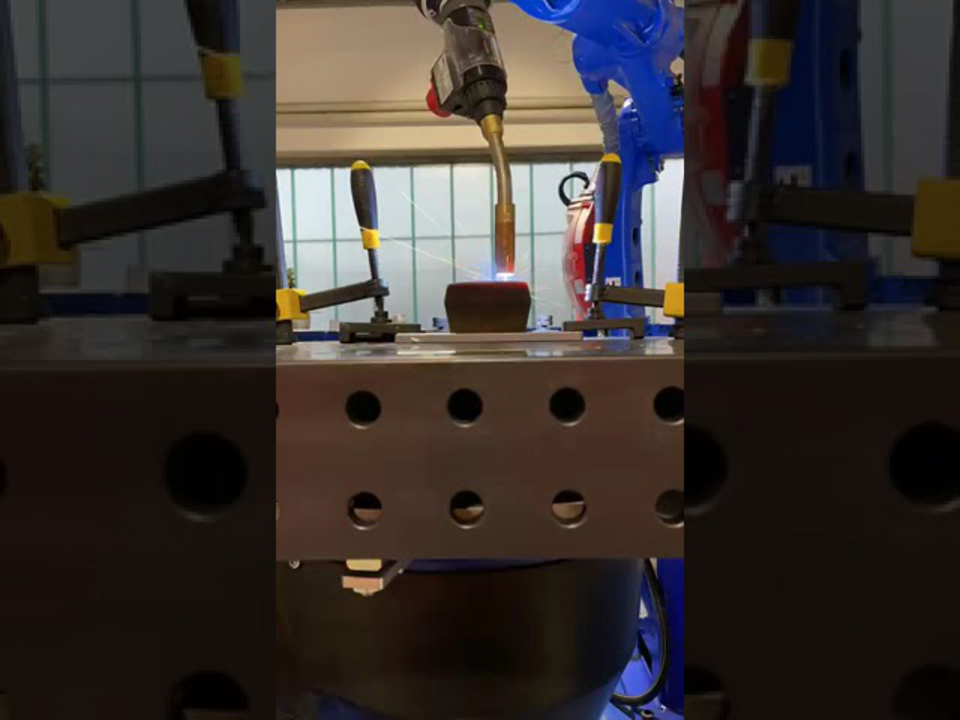

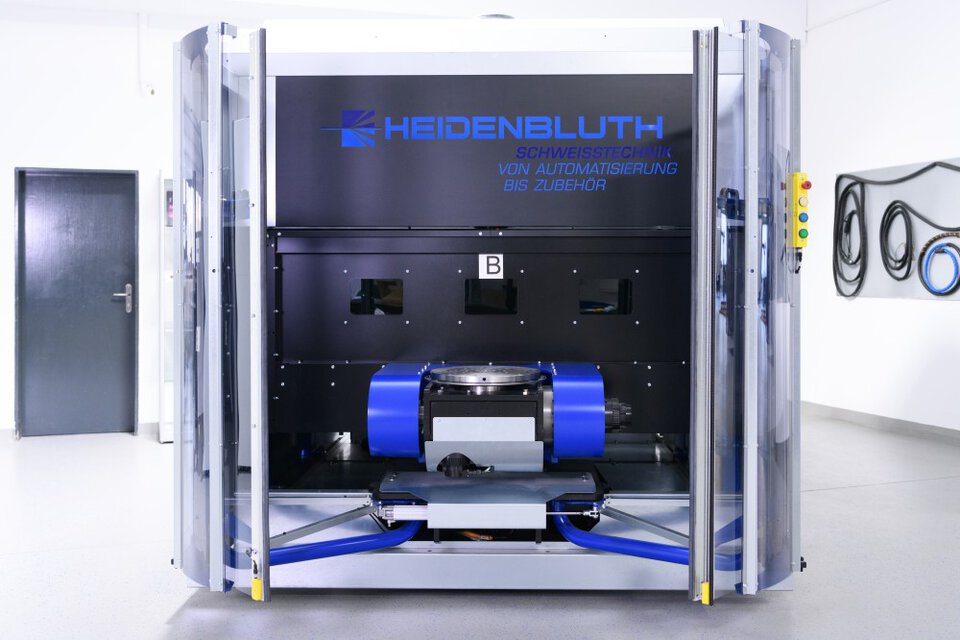

State-of-the-art technology is used in the system setup for additive manufacturing with robots.

The FRONIUS WAAM welding equipment is precisely guided by a Yaskawa industrial robot. The component is manufactured on a specially selected positioner, which is adjusted according to the size and weight of the component to ensure optimal manufacturing positions.

Furthermore, it is possible to selectively cool or heat the component during manufacturing to control the material properties and ensure high quality. Specially developed software handles the robot's path planning, thus guaranteeing precise and efficient manufacturing of complex components in the WAAM process.

- CE Declaration of Conformity for the entire system

FRONIUS WAAM technology with push-pull system

- Support for process planning (quality values)

- Robot path planning software

- Thermal intervention options