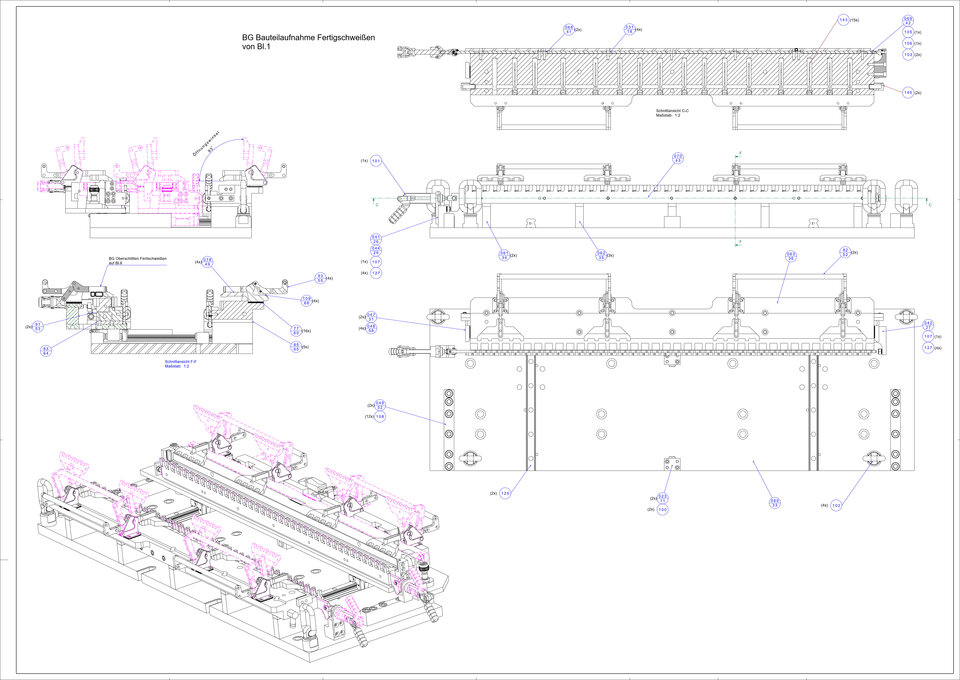

Component holder for welding robot

Depending on the quantity to be produced, one can choose between different types of partial shots.

For small batch sizes, the clamping system from Siegmund is ideal. Its modular system allows for the precise fixing of components. Thanks to the zero-point clamping system, the components can then be easily removed, stored, and re-clamped when needed for further production. Locking is achieved either manually or pneumatically.

For larger quantities, various additional requirements come into play:

- Pneumatic clamping of components (time saving)

- Integrated water cooling to cool the recording due to the long welding time

- Internal shaping of the components

Component images – the basis for successful robot manufacturing

A key component of successful robotic manufacturing is the component holder .

It ensures the optimal positioning of the individual parts and prevents unwanted component distortion during the welding process.

To tailor the entry into automated manufacturing to individual needs, we offer various service packages .

This ensures reliable and efficient component handling from the outset – the basis for stable processes and high-quality welding results.

Design & Documentation

- We design the component fixture and create drawings and the required parts list from it.

- Welding accessibility and thermal influences are already taken into account during the design phase .

- Depending on requirements, manual or automated devices are created that can be integrated into the robot control system (pneumatic or electric).

- The manufacturing of the devices is carried out by the customer himself (e.g. in his own toolmaking department) or by a partner company.

Complete package including manufacturing

- In addition to the design, we also handle the manufacturing of the component fixture together with our partners .

- We will oversee the integration of the components into the system.