Welding Package Starter or Advanced

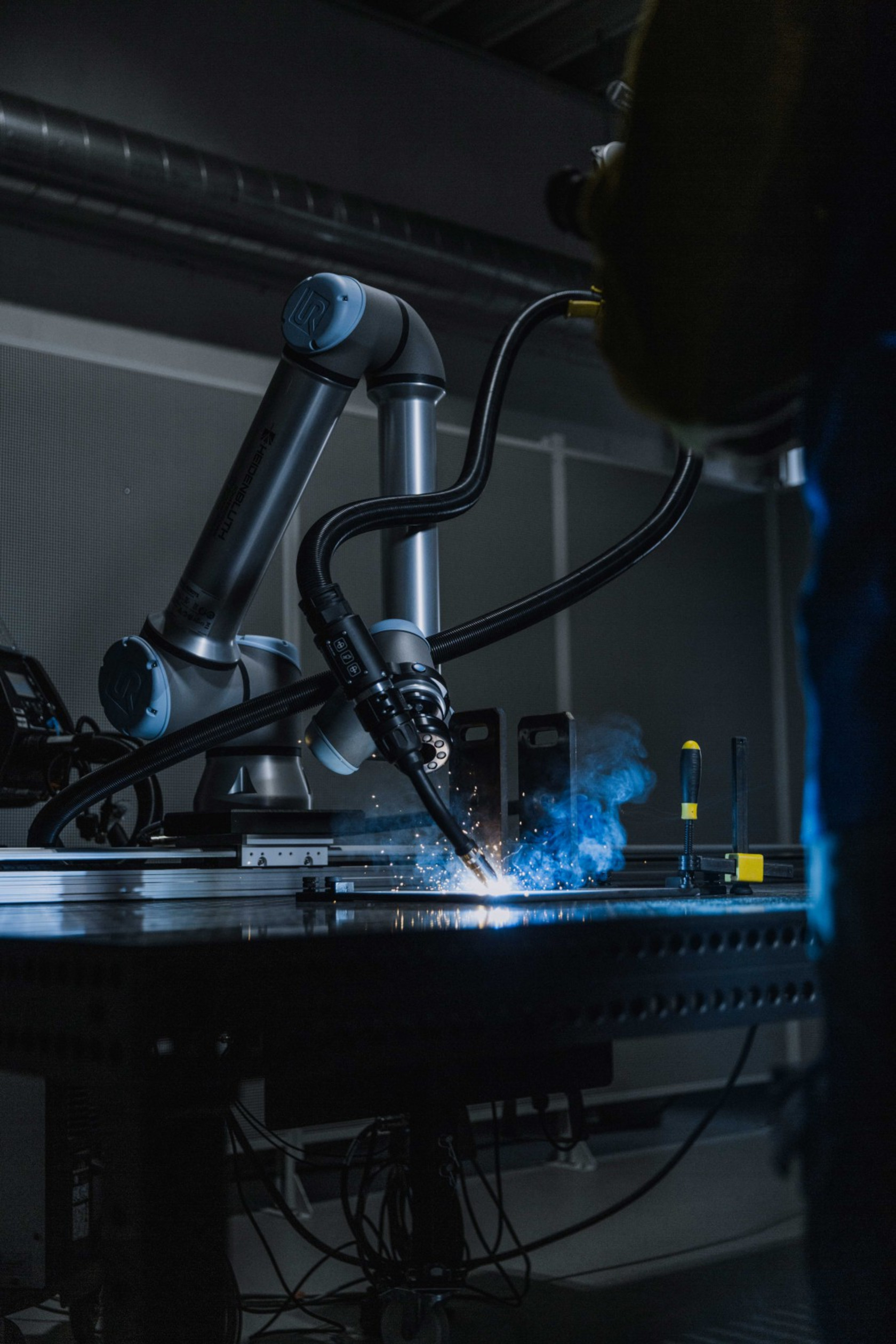

Heidenbluth's Cobot Welding Packages offer a modern and innovative solution for automated welding that can be seamlessly adapted to the specific requirements of production.

This robotic welding concept is flexible and individually configurable, enabling exceptional adaptability to a wide variety of manufacturing environments and processes. This means that regardless of the production line design, the Cobot Welding Packages can be precisely tailored to the specific on-site conditions, thus offering a future-proof investment in automation.

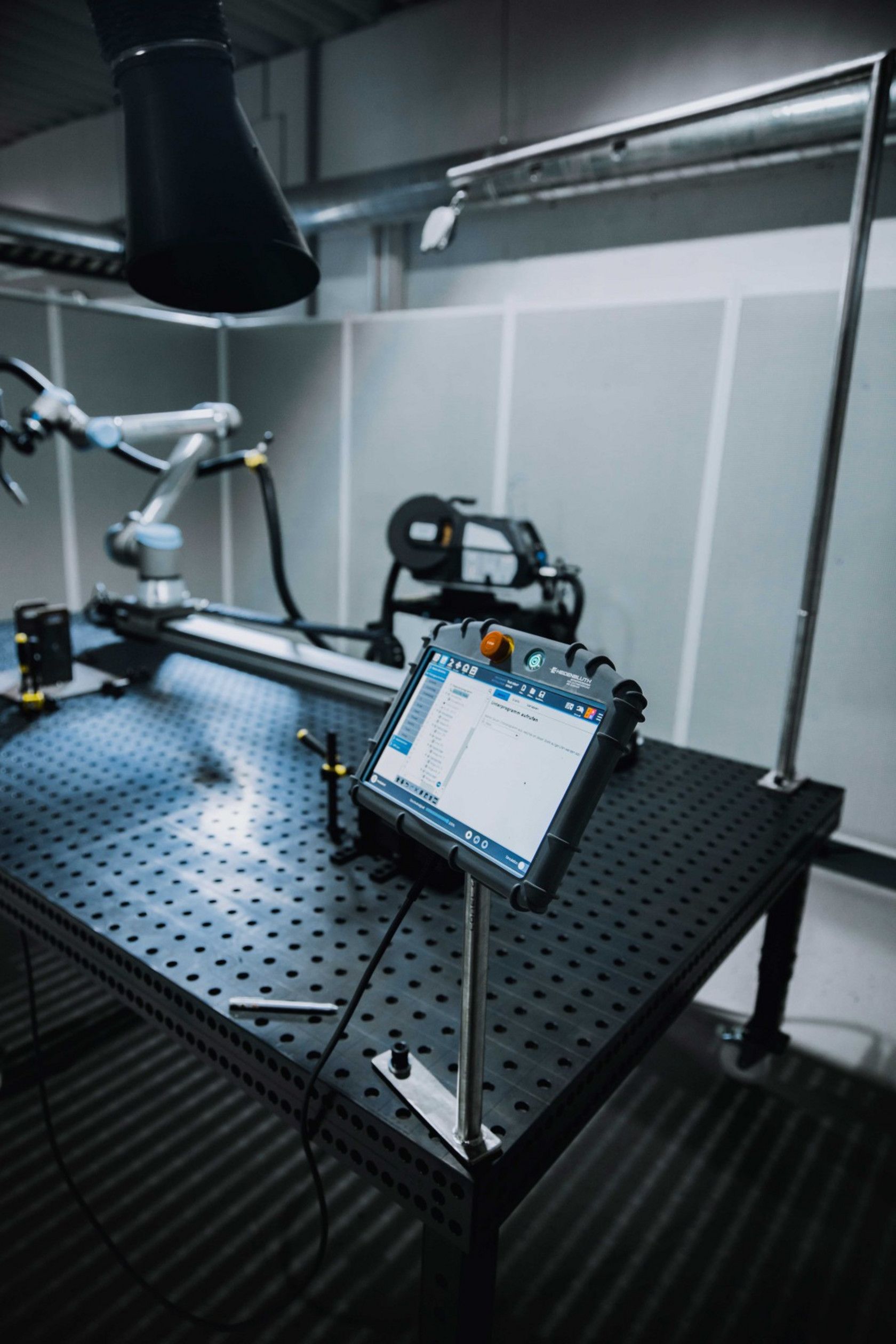

![[Translate to English:] Heidenbluth - Welding Package [Translate to English:] Heidenbluth - Welding Package](/fileadmin/_processed_/c/5/csm_Heidenbluth_038_c72b85778f.jpg)

- 1

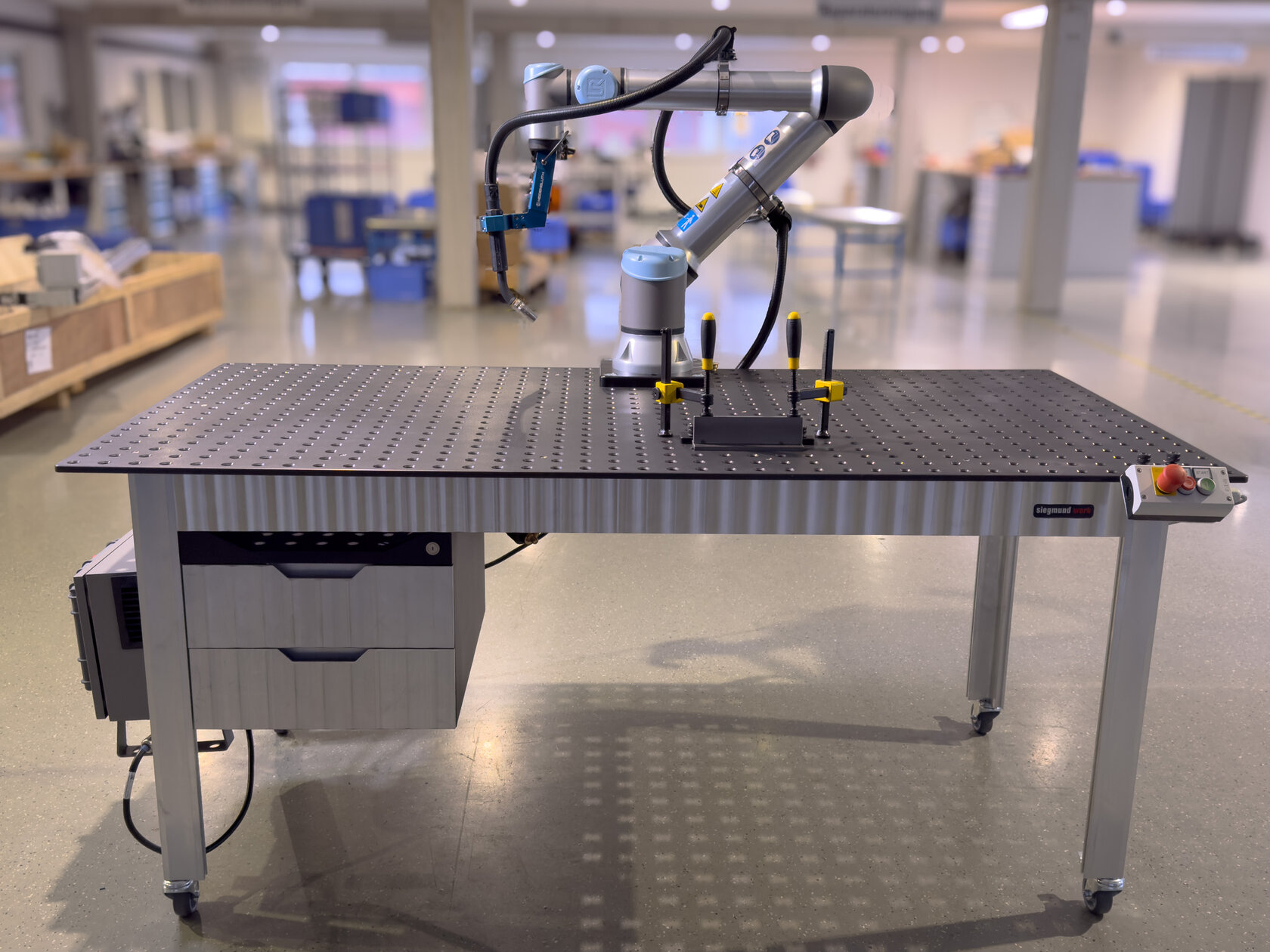

Siegmund welding table

- 2

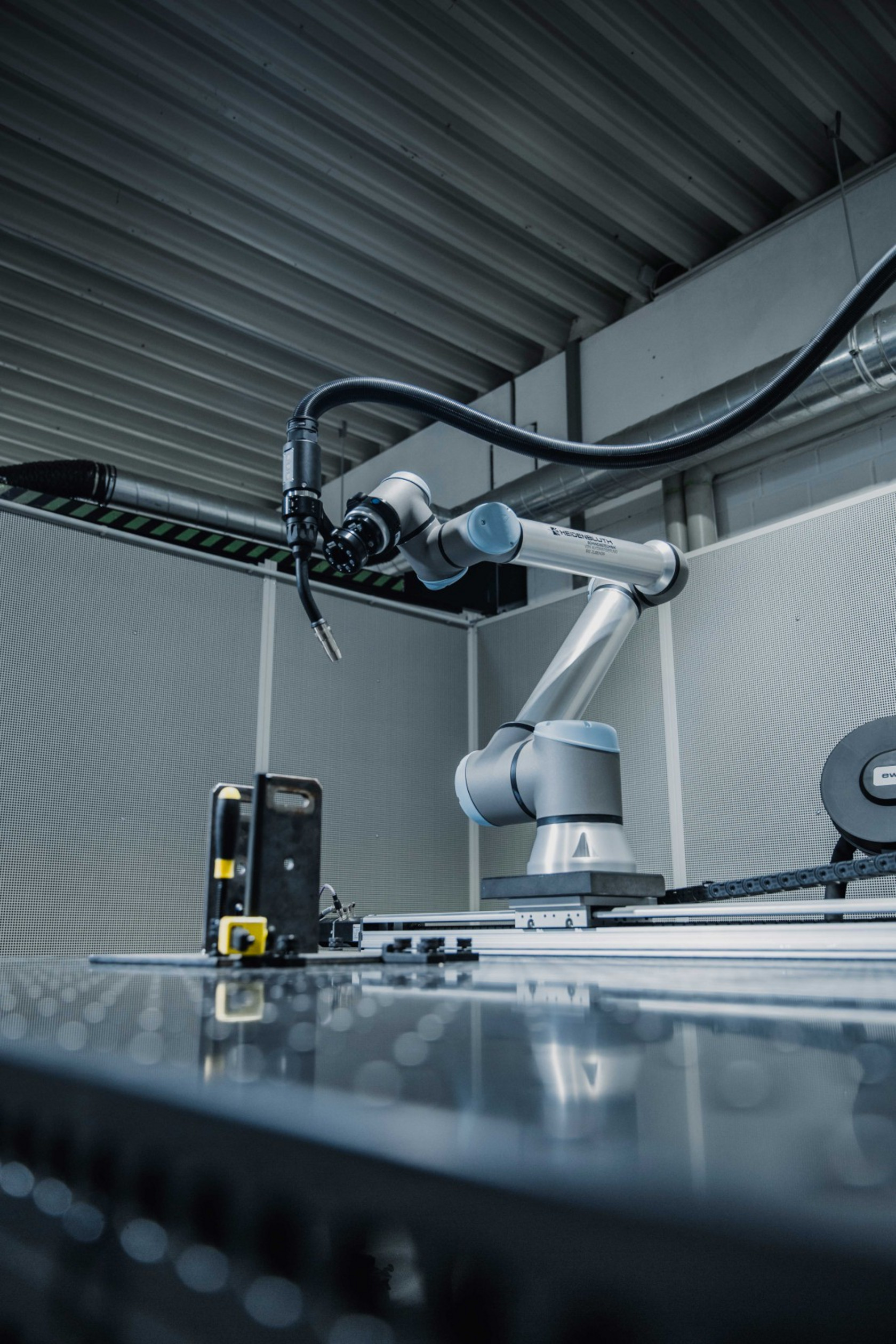

Cobot from Universal Robots

- 3

Linear axis

- 4

Different welding processes

- Convenient access to the welding area without interfering contours for loading and unloading.

- The cabin can be freely configured in terms of size and flexibility.

- Self-built enclosure after agreement on minimum requirements

- Siegmund welding tables offer space for all assemblies

- Mounting the robot on the table or optionally on the back wall

- Standard enclosure, soundproof enclosure or optional self-build

- including safety technology

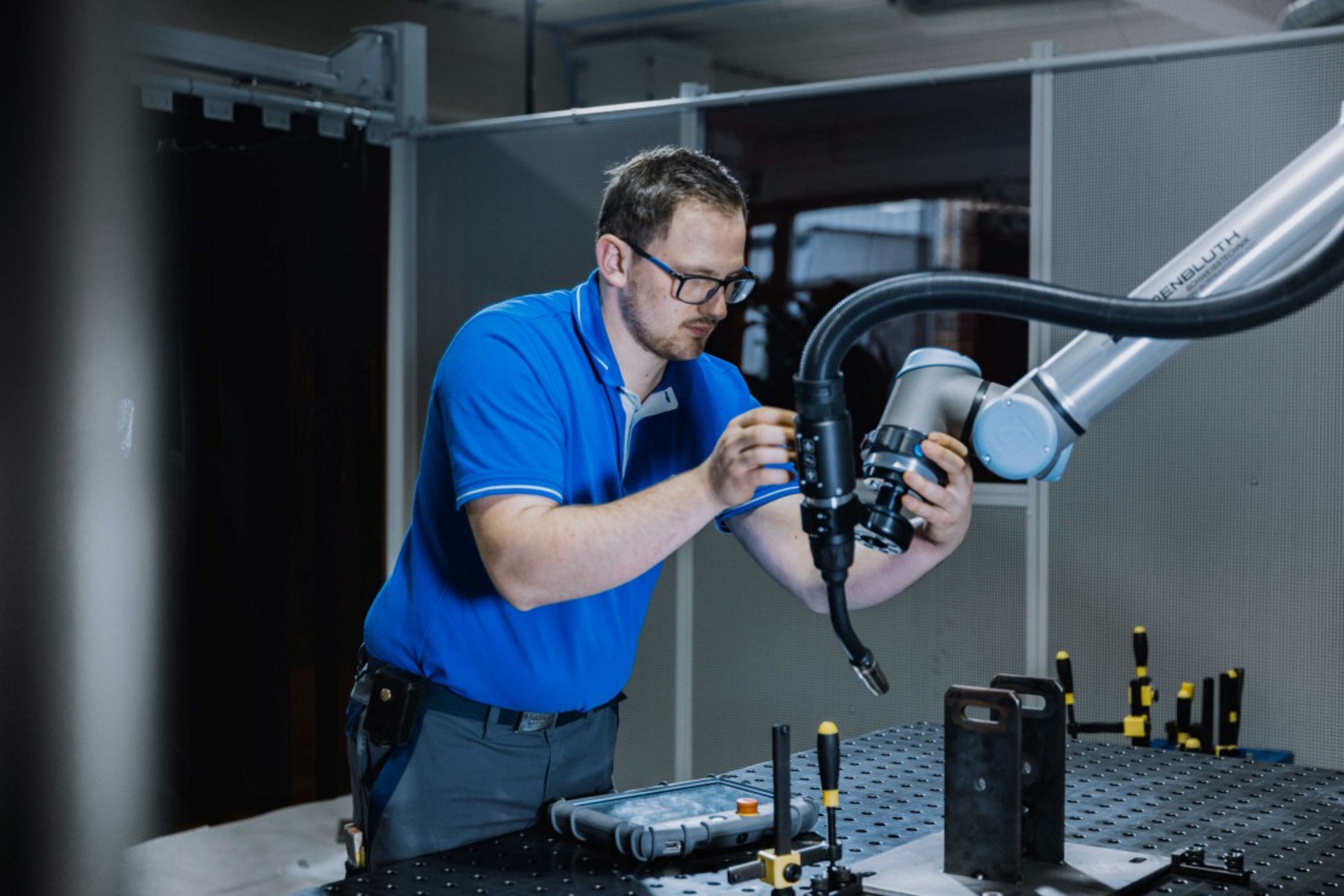

- Installation and commissioning by our technicians at a fixed price

- On-site training by our technicians at your location for a fixed price

- Welding processes : Supports MIG/MAG and TIG processes, ideal for different applications and materials.

- Robot arm reach : Up to 1,300 mm, for flexible adaptation to different workpiece sizes.

- Robot payload capacity : 5 to 10 kg, suitable for most welding applications in industrial environments.

- Repeatability : ± 0.03 mm, ensuring high precision and consistent weld quality.

- Control and programming : Touchscreen and offline programming enable simple and intuitive operation.

- CE certification for the entire system : legal certainty and full conformity, thus eliminating the need for a separate risk assessment.

- MIG/MAG from EWM

- MIG/MAG from Fronius

- CMT - Cold Metal Transfer by Fronius

- WIG-DC from EWM

- EWM TIG AC/DC

- TIG DC with cold wire feed from EWM

- TIG AC/DC with cold wire feed from EWM

- With protective film for UR e-Series

- With protective cover for control panel

- Cobot LED Lighting traffic light

- Pneumatic zero-point clamping system for holding Siegmund interchangeable plates

Welding Package Starter

The Welding Package Starter Package with MAG/MIG welding technology.

- Table size variable

- Robot type UR 5e or UR 10e "Ready to weld"

- Software packages for easier operation

- CE declaration for the entire system

- MIG/MAG welding technology Fronius and EWM

- Zero point clamping system

- burner extraction

Welding Package Advanced

The Welding Package Advanced includes TIG welding technology and extensive accessories.

- Table size variable

- Robot type UR 5e or UR 10e "Ready to weld"

- Software packages for easier operation

- CE declaration for the entire system

- MIG/MAG welding technology Fronius and EWM

- Zero point clamping system

- burner extraction

- Linear axis for moving the robot

- Rotary table for component positioning

- Rotary and tilting table for component positioning

- TIG welding technology from Fronius or EWM

The Cobot Welding Package in use

Heidenbluth's Cobot Welding Packages are a sophisticated and future-proof solution for industrial welding automation. They combine flexibility, legal compliance, and user-friendliness in a single concept. Thanks to the CE declaration of conformity for the entire system, additional costs and the effort of a risk assessment are eliminated. The combination of ease of use, flexible welding processes, and high efficiency makes Heidenbluth Welding Packages the ideal choice for companies that want to automate their manufacturing processes while maintaining high quality standards and production safety.