The BigArc welding cell is the ideal entry point into productive, automated welding.

The BigArc's two-station solution significantly increases your productivity. The cell is particularly well-suited for small and medium production runs. While the robot welds at one station, the operator can load the system with new components at the other two stations.

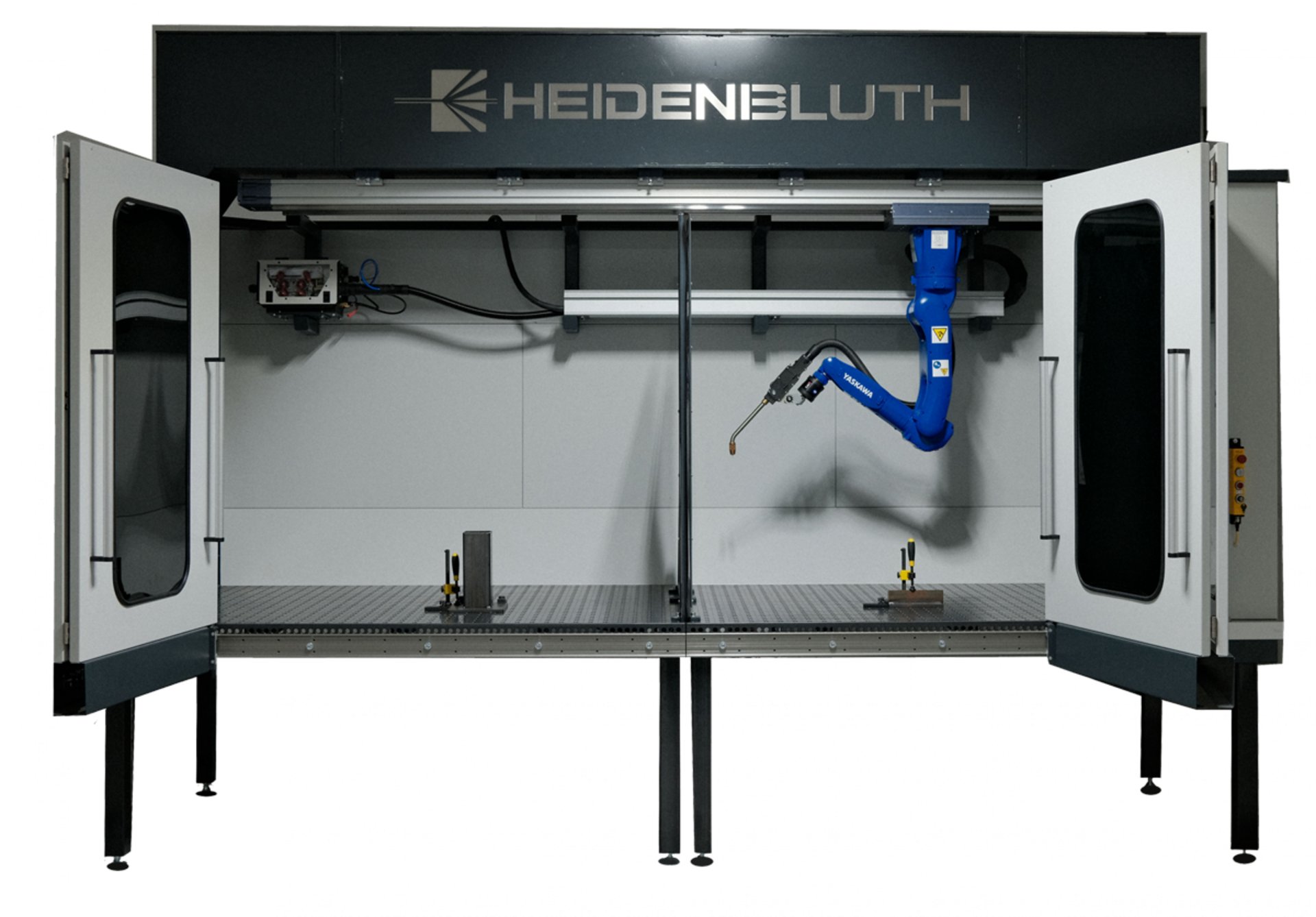

The CE declaration is included from the start, thus offering optimal protection for your employees and your surroundings. Another advantage is the removable safety partition, allowing for the production of large assemblies. This ready2weld BigArc robotic welding system with two stations is fully enclosed and equipped with a Yaskawa industrial robot and a horizontal displacement axis. This system therefore offers the highest level of protection for employees against sparks, dangerous UV radiation, and burns from the hot wire end.

- Easy to use

- High security thanks to comprehensive security technology

- Easy commissioning and training of your team by our application engineers on site

- Two-station system with high productivity

- CE Declaration of Conformity for the entire system

- MIG/MAG from EWM

- MIG/MAG from Fronius

- CMT - Cold Metal Transfer by Fronius

- WIG-DC from EWM

- EWM TIG AC/DC

- TIG DC with cold wire feed from EWM

- TIG AC/DC with cold wire feed from EWM

- stud welding technology

- Pneumatic zero-point clamping system for holding Siegmund interchangeable plates

Another advantage of this automation solution is the two-station concept. While the robot performs its welding task at the first station, the operator can load the second station, significantly increasing productivity.

The offered cell concept includes a CE declaration of conformity. This applies not only to the robot but to the entire welding system. The time-consuming and costly effort of a hazard analysis and risk assessment for you as the operator is therefore eliminated, and this is another significant advantage of this complete automation solution.

- 1

Optional: Various door and enclosure concepts with certified security technology

- 2

Optional: Linear axis for moving the robot

- 3

Two welding stations for maximum productivity

- 4

Yaskawa industrial robots

![[Translate to English:] Zwei-Stationen-Lösung BigArc](/fileadmin/_processed_/c/2/csm_IMG_2869_dfbf2a290f.jpg)

Maximum flexibility and productivity – with the BigArc two-station solution

BigArc's innovative two-station solution takes your productivity to a new level – the system truly shines when dealing with small to medium production runs. While the robot performs precise welding at one station, the setup of new components can begin simultaneously at the second station – without any loss of time.

With just a few simple steps, the partition wall can be removed, transforming the cell into a high-performance single-station welding system in no time – ideal for larger workpieces. The integrated safety control automatically detects the selected operating mode and adjusts the safety functions accordingly.