Welding robot cells with Universal Robots – Efficient automation for welding technology

Welding robot cells from Universal Robots offer a flexible, cost-effective, and high-quality solution for companies looking to automate their welding processes. Universal Robots' collaborative robots (cobots) enable precise and repeatable welding operations, increasing both productivity and manufacturing quality.

Welding robot cells with Universal Robots offer a future-oriented way for companies to optimize their production and remain competitive. Their ease of use, flexibility, and efficiency make these cobots a worthwhile investment. With their diverse applications and economic advantages, they are particularly attractive for companies that want to automate their welding processes cost-effectively and with the highest precision.

-

Downloads

Heidenbluth Automationsbroschüre EN 2025

- Advantages of welding robot cells

- Application areas

- Welding technologies and compatibility

- Advantages of automation

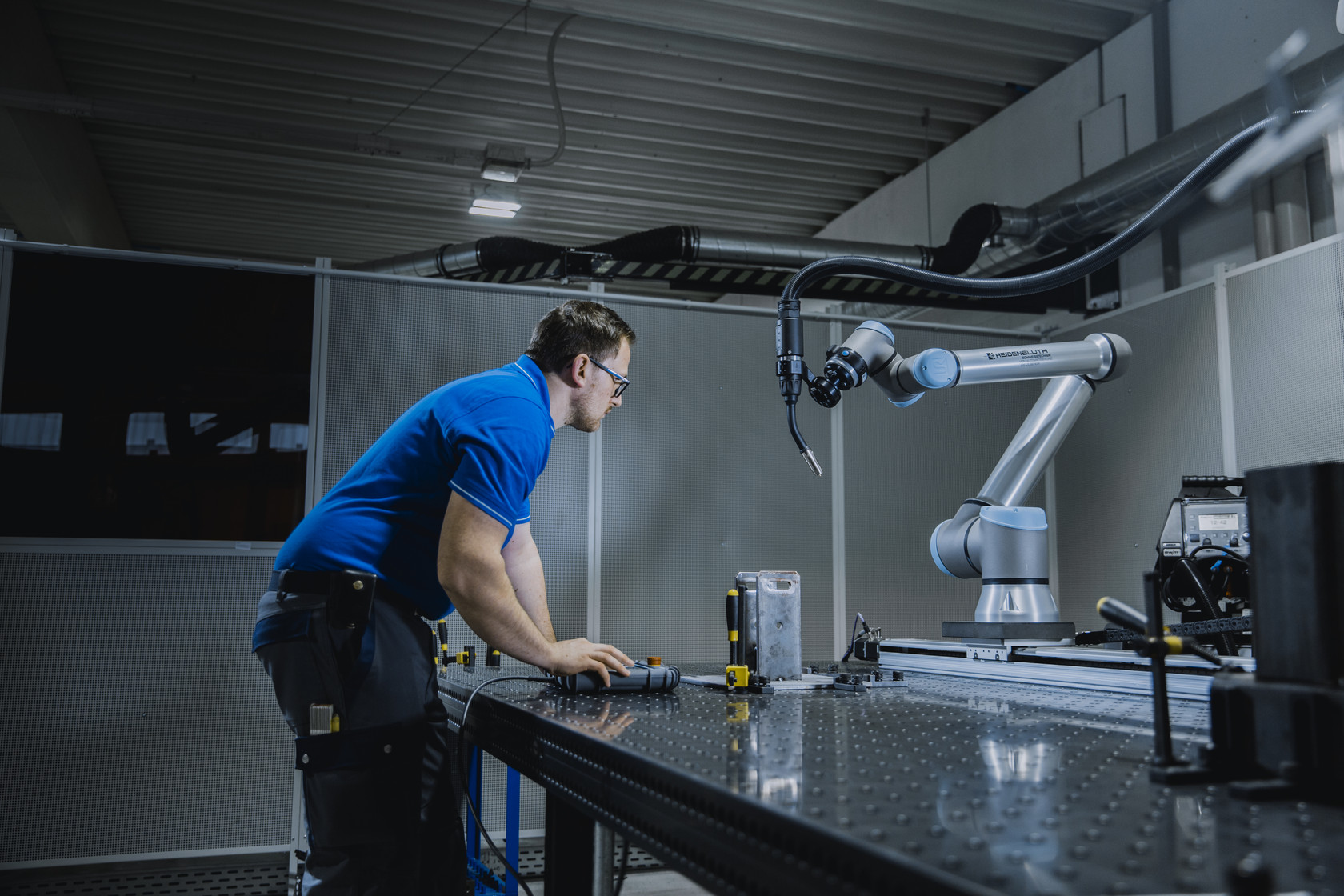

- Flexibility and easy programming:

Unlike conventional robot systems, Universal Robots are easy to program and can be used flexibly for various welding tasks. Intuitive user interfaces allow even employees without specialized robotics knowledge to control and adjust the robot. - Precision and consistency:

Welding robot cells enable repeatable welding operations, which is particularly important for series production. This reduces material consumption and scrap – an advantage for quality and cost savings. - Universal Robots offers collaborative robot technology

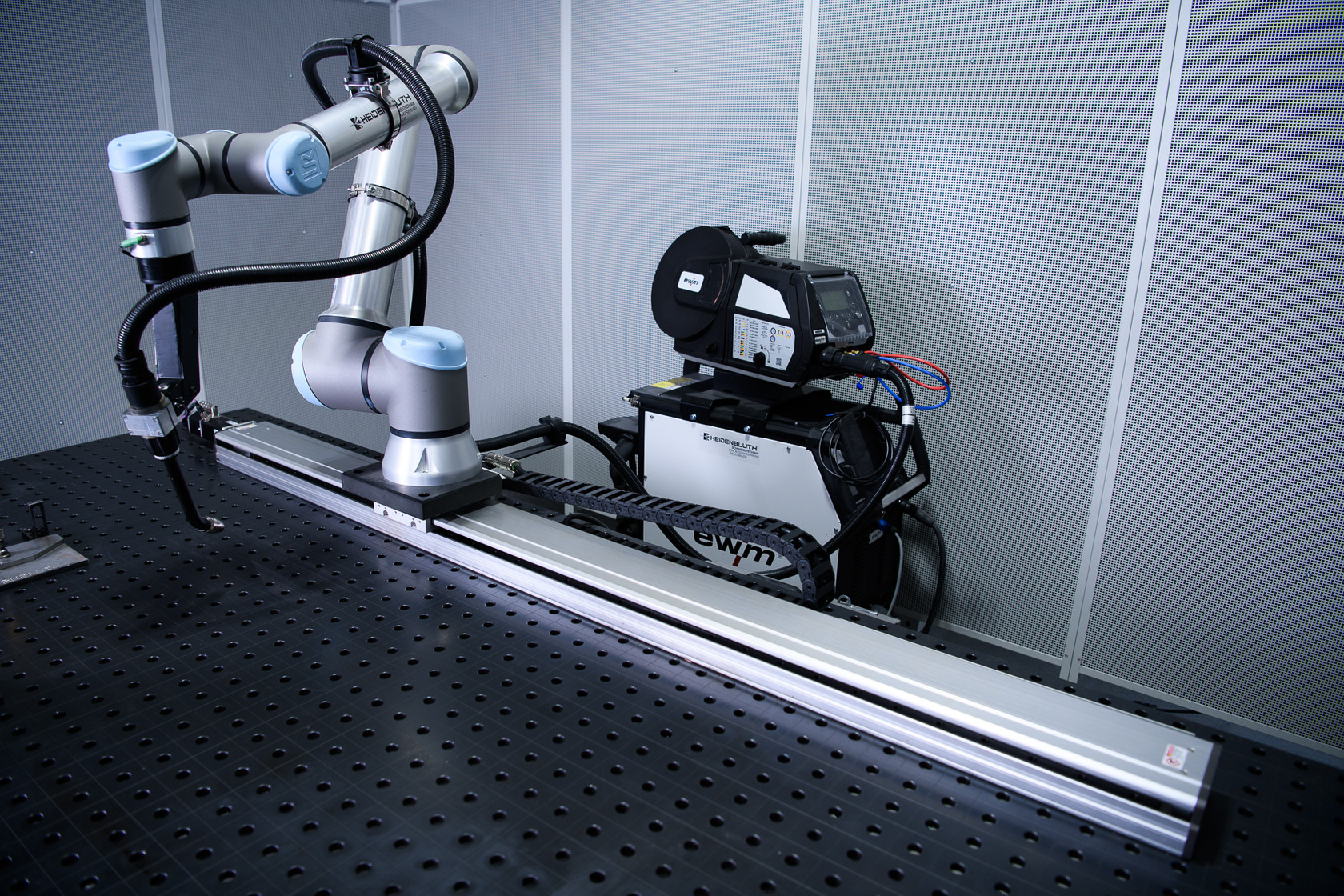

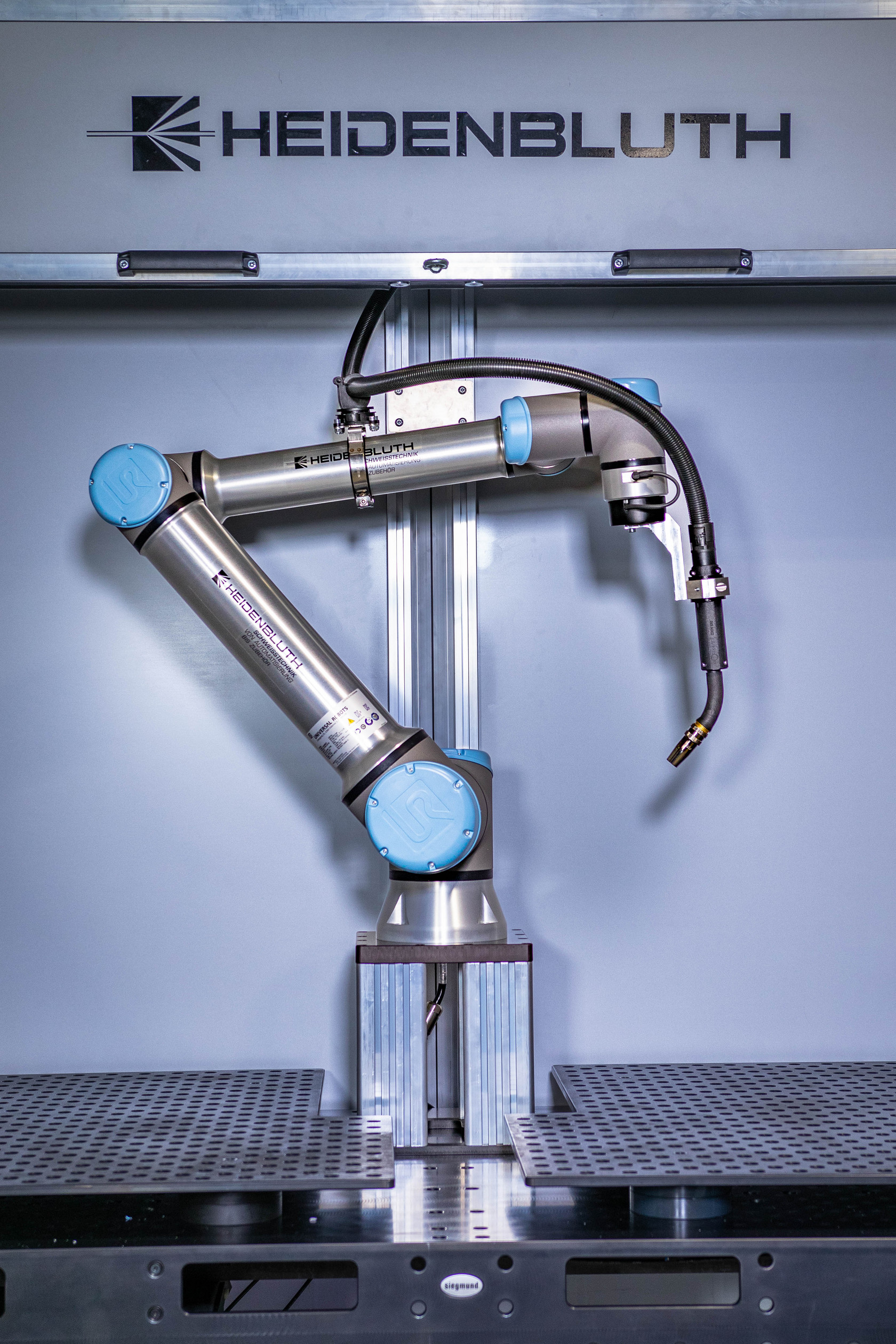

, including cobots specifically designed to work safely alongside humans. They can be integrated into manufacturing environments without the need for safety fences or barriers and can be operated safely in close proximity to human workers. - Space-saving integration:

Thanks to their compact design, the welding robot cells can be easily integrated into existing production lines. They require less space than traditional robot cells, making them particularly attractive for small and medium-sized enterprises.

Application areas for welding robot cells with Universal Robots

Welding robot cells are versatile and suitable for various industries, such as the automotive, metal, mechanical engineering, and furniture industries. Typical applications include welding sheet metal, pipes, and assemblies . Thanks to the flexibility of cobots, even complex weld seams or 3D welding patterns can be processed efficiently.

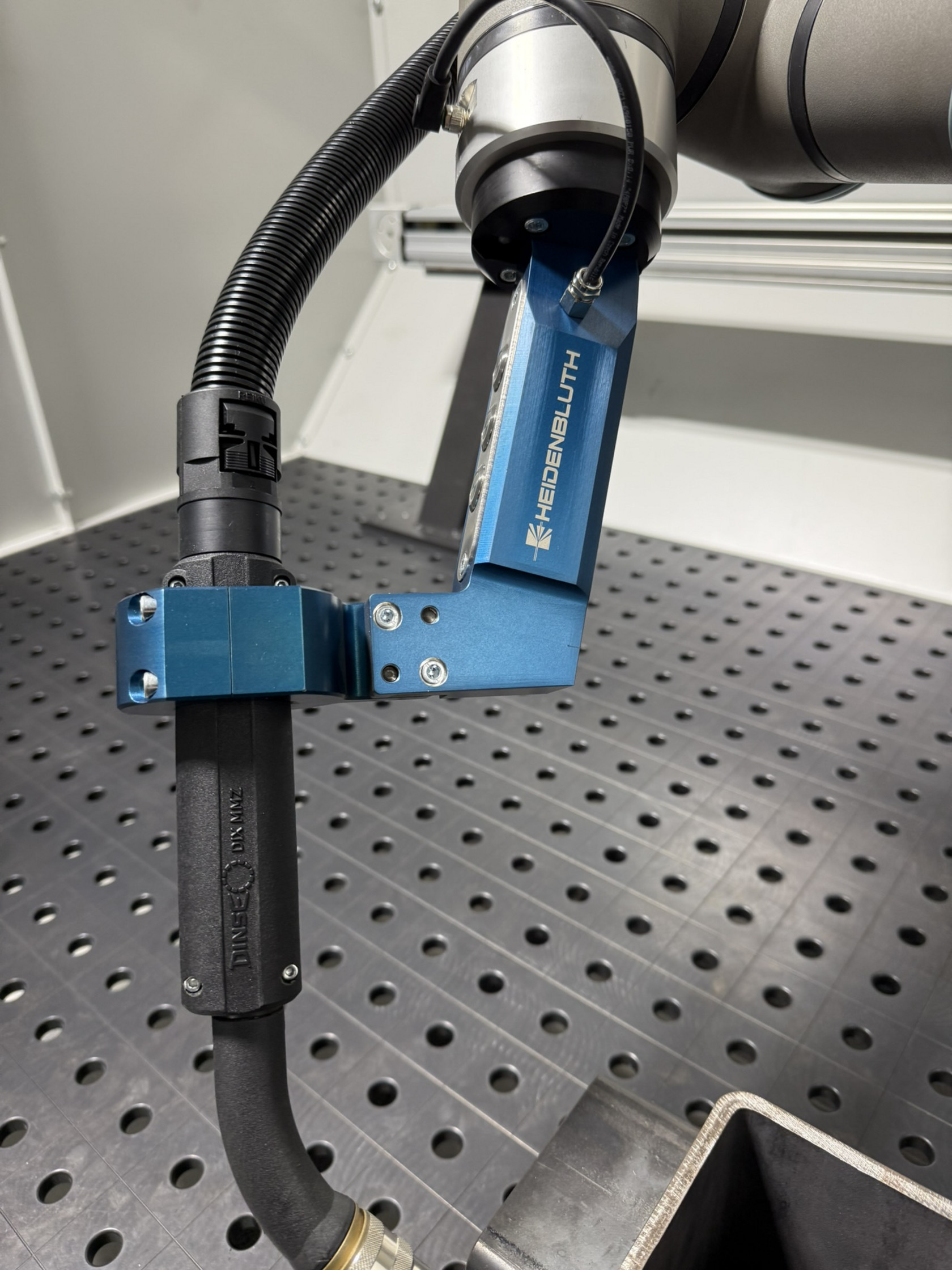

Universal Robots' welding robot cells are compatible with various welding processes, including MIG/MAG welding, TIG welding, and plasma welding . This compatibility enables a wide range of welding techniques and facilitates adaptation to specific production requirements.

By using welding robot cells, companies can save costs in the long term. The automated welding process reduces dependence on manual labor and minimizes the risk of errors and rework. Furthermore, automation enables continuous production, thereby reducing lead times and avoiding production bottlenecks.