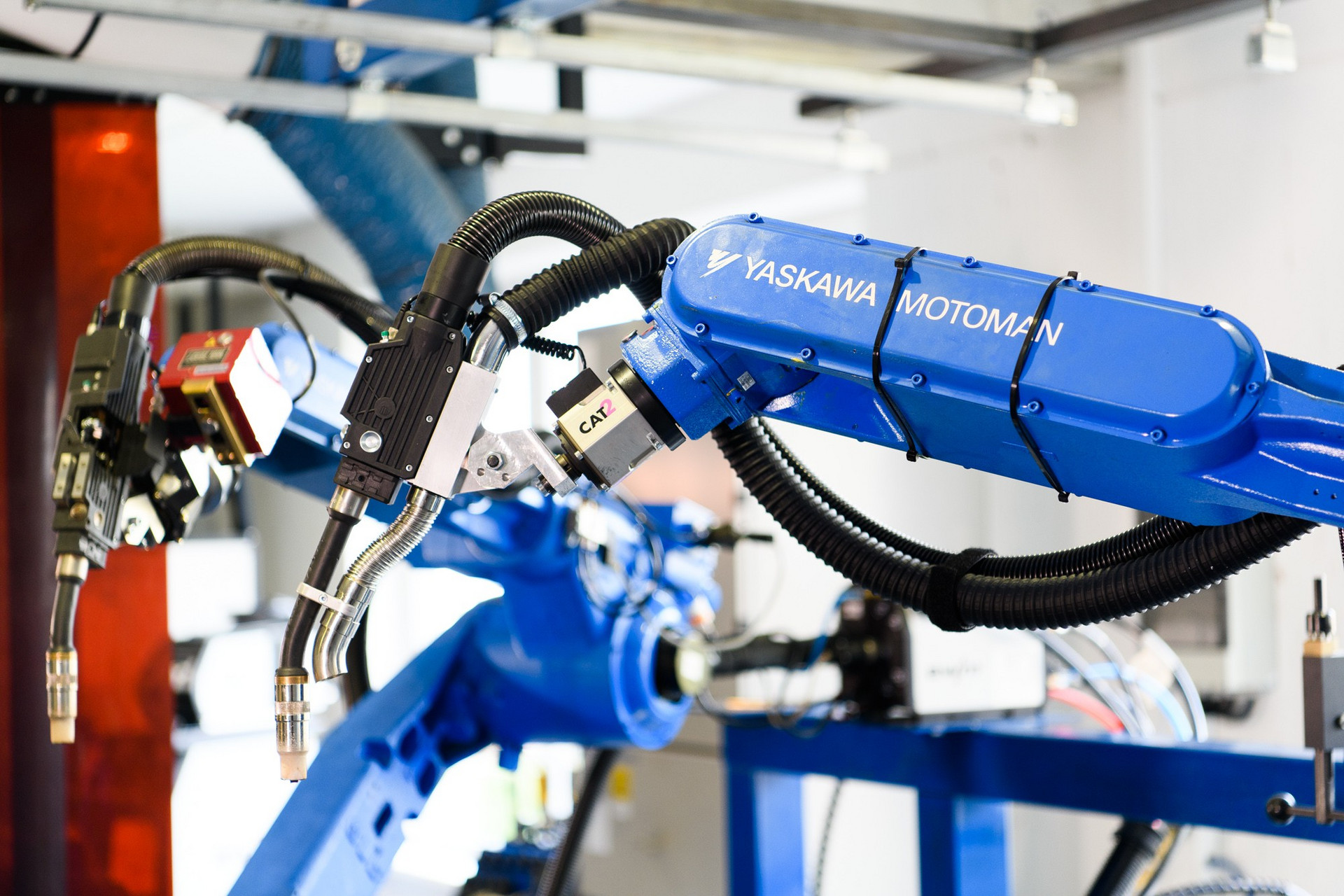

Accessories for Welding Robots

Our product range includes accessories specifically tailored to the requirements of Yaskawa Motoman and Universal Robots. This encompasses both mechanical and electronic components that can be easily and quickly integrated into existing systems. The result: more efficient workflows, reduced maintenance times, and higher weld quality.

Why the Right Accessories Are Crucial for Welding Robots

Welding robots work quickly and precisely, significantly reducing labor in production.

However, the right accessories not only improve efficiency but also increase the robots' flexibility and lifespan. Whether welding torches, protective covers, cleaning systems, or positioners – each accessory fulfills a specific function and contributes to optimizing the entire welding process.

TOUCH SENSE

Tactile scanning via the wire end or gas nozzle.

Touch Sense uses the free wire end or gas nozzle to scan the position of the component. The robot's program is then automatically corrected, ensuring a reliable welding process.

SEAM TRACKING

Seam tracking via voltage monitoring.

Seam tracking, or automatic seam tracking, is also possible for fillet welds using arc voltage. The robot's oscillating motion uses the arc length to determine the root point. This allows for automatic adjustment of the travel paths in case of component distortion or tolerances during the welding process.

WIRE SENSE

Seam detection via pulsating wire

Wire Sense is also known as wire detection. A high-frequency forward and backward movement of the wire detects the component and automatically corrects component positioning errors.

WELD SEAM TRACES CAMERA

Our weld seam cameras support your robots in weld seam detection and tracking.

These compact cameras, optimized specifically for welding and cutting, are characterized by high speed and accuracy. We would be happy to assist you in selecting the right camera system and explain the advantages of arc seam tracking.

WELD SEAM TRACKING CAMERA

This camera system allows you to monitor and correct the weld seam live during the welding process.

This enables you to react to component distortions during welding, among other things.

BURNER EXTRACTION SYSTEM

Our burner extraction system extracts fumes right where they are generated.

Process-reliable, efficient, and environmentally friendly.

TORCH CLEANING STATION

Process reliability in automated welding through preventative torch cleaning, wire cutting, and anti-spatter protection with the TCS Compact!

Optimal and time-saving gas nozzle cleaning for a reliable welding process and increased system availability. Test it live with us now.

TORCH CHANGE SYSTEM

With an automatic torch change system, the welding robot can be equipped with various welding systems via a programmatic control system.

It makes no difference whether it involves two MAG systems with different welding consumables, or switching between MAG, TIG, stud welding, or plasma welding to complete an assembly.

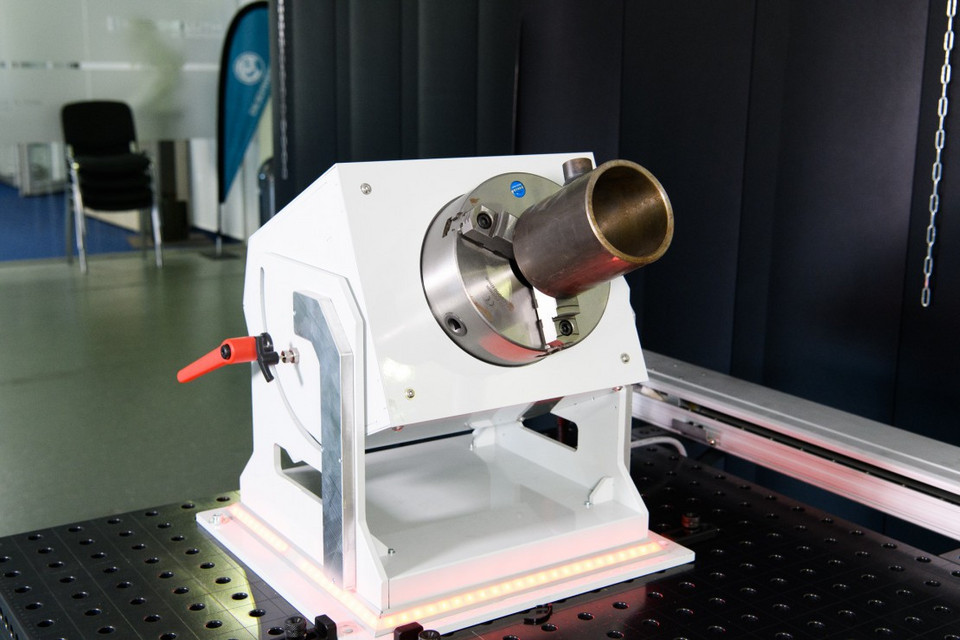

Rotary Tilt Tables & Positioners

We offer a wide variety of positioners and rotary tilt tables.

Depending on component ergonomics, welding position, and weight, we select the appropriate positioning technology for you. Full synchronization capabilities allow for optimal coordination of accessories and robot movements. Operation is intuitive via a programming handheld device.

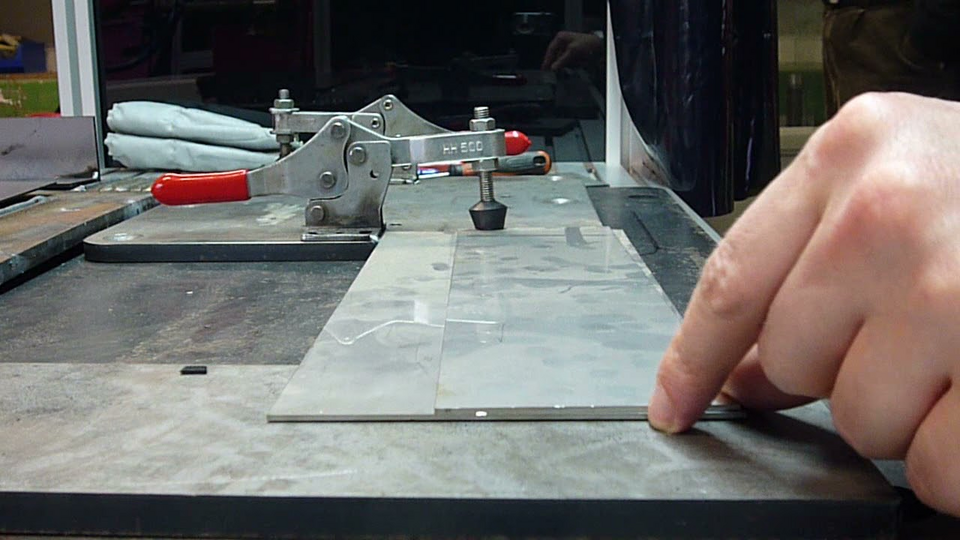

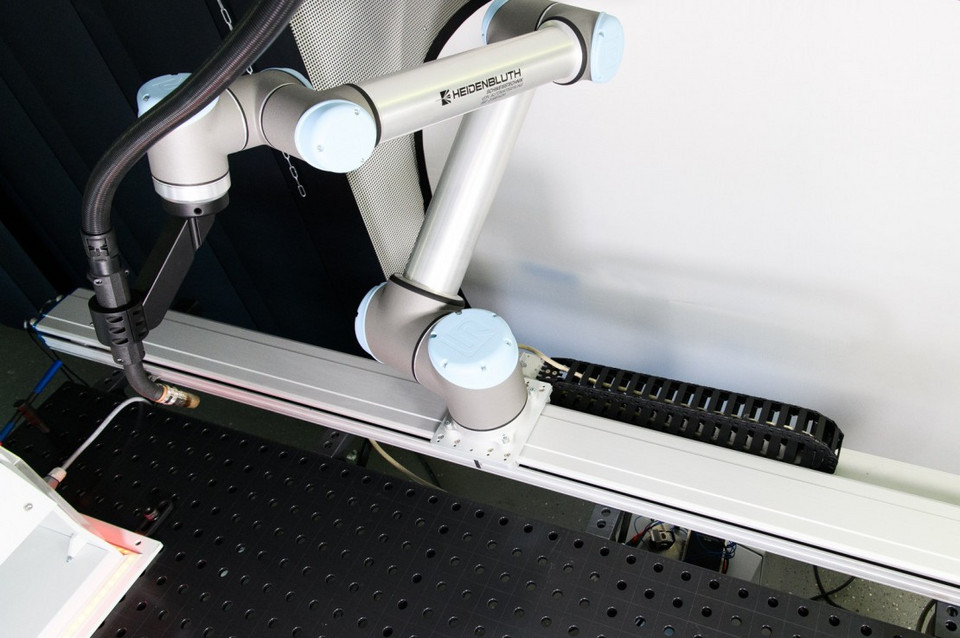

FLOOR DRIVE

Floor drives enable the welding robot to be quickly moved to the desired welding position.

A floor drive is a particularly useful addition for larger components. Mounting it on gantries further extends the robot's reach.

CONTACT NOZZLE CHANGER

The contact nozzle changer enables the robot to change its contact nozzles independently and fully automatically at predefined intervals.

Integrated gas nozzle cleaners and wire cutters further reduce downtime and eliminate potential damage caused by incorrect nozzle selection.

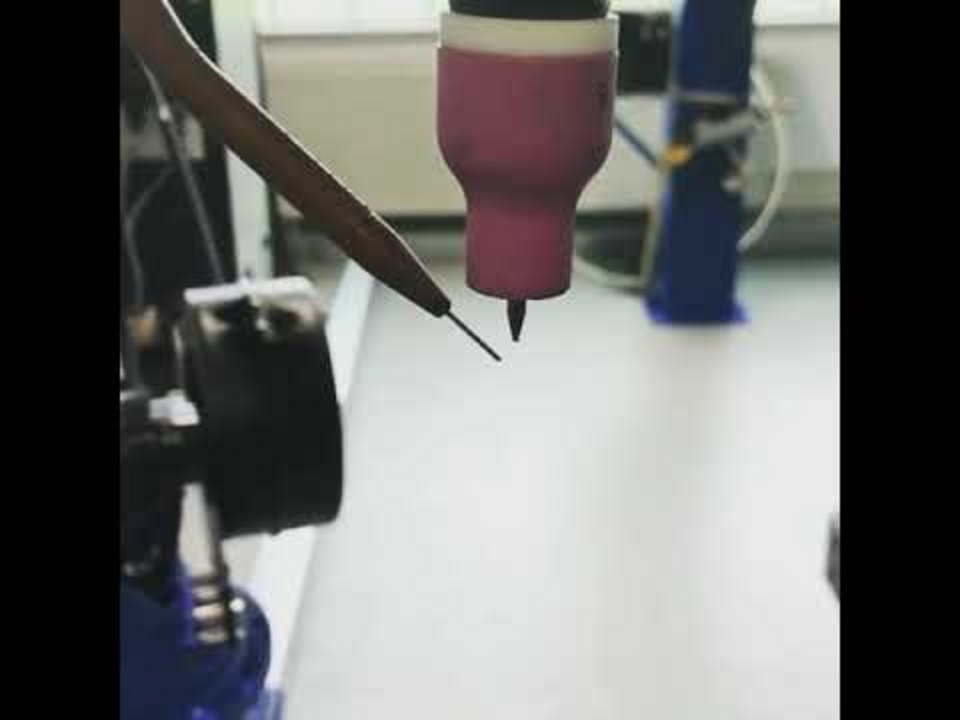

AUTOMATIC TUNGLASS NEEDLE CHANGE SYSTEM

The automatic tungsten needle change system consists of a robotic hose assembly and a tungsten needle changer. This system is designed for use with a hollow-shaft robot. This reduces the hose assembly's obstructions and improves accessibility.

Furthermore, the optimized wire feed is significantly improved due to its linear operation. The automatic tungsten needle changer further enhances the system. The robot automatically deposits the used tungsten needle and is then automatically fitted with a new one. The needle length is then set to the robot's TCP (Torque Transfer Controller), and the manufacturing process can continue. All of this occurs without operator intervention, and the needle length is always correctly tensioned.

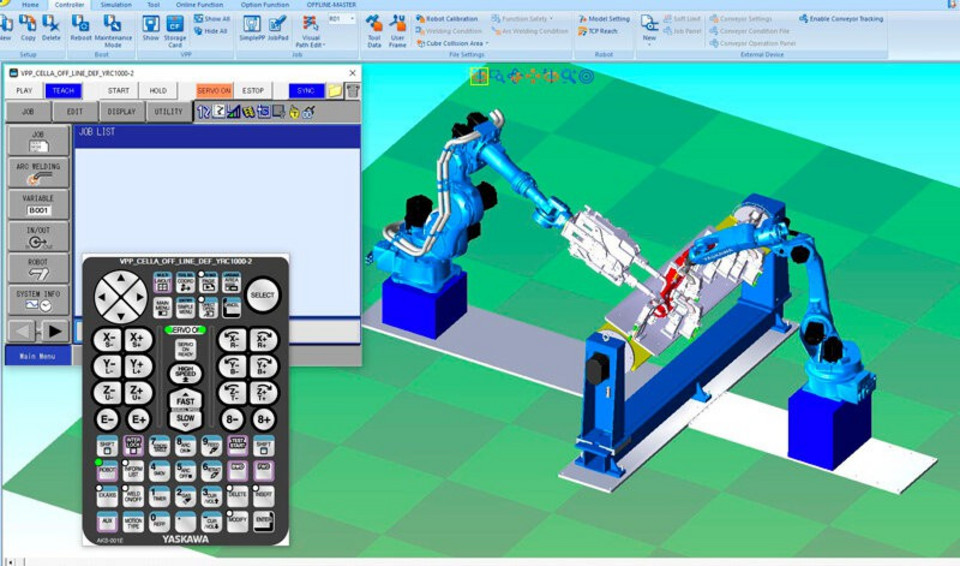

OFFLINE PROGRAMMING OF WELDING ROBOTS

Virtual simulation of robot-based systems and processes offers significant advantages not only during the planning phase, but also during commissioning and subsequent operation.

This allows costly errors to be avoided in advance and existing resources to be used efficiently.